How Do Stirling Engines Work? History, Types & Uses

-

- Last updated:

Since the Industrial Revolution, many engines have been producing energy for consumption. First, there were steam engines that were powered using coal. These days, there are cleaner and more efficient engines such as piston engines, rotary engines, and boxer engines. But, one engine type has stood the test of time: the Stirling engine.

A Stirling engine is a heat engine that operates by cyclic compression and expansion of air or other gasses (the working fluid) at different temperatures. This engine is the perfect choice for renewable energy applications. It uses much less fuel than conventional engines. It’s also quiet and produces no emissions at all!

The engine depends on the regenerative principle that allows it to convert around 50% heat into helpful work. So, it’s more efficient than any other heat engine. Besides, unlike other closed-cycle heat engines, it can start and operate without any external power source or prime mover.

To know how Stirling engines work, we’ve created this helpful guide. Keep reading to learn more about Stirling engines’ operation and other crucial aspects of this engine.

How Does a Stirling Engine Work?

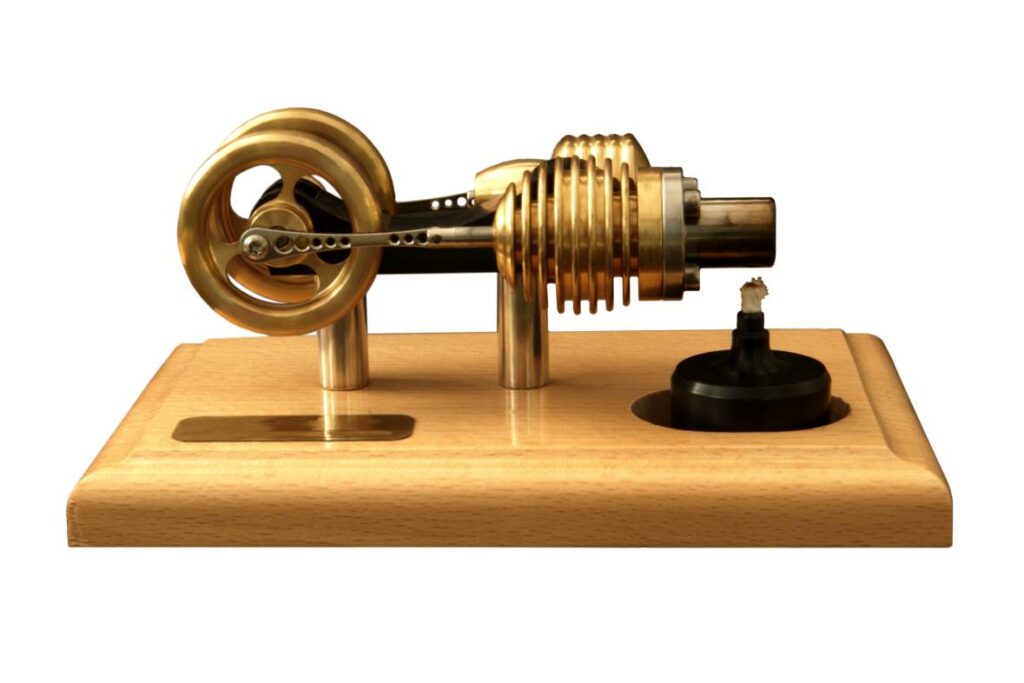

Stirling engines are heat engines that use regenerative cooling. They generate mechanical power and convert heat into mechanical energy. So, they deliver net positive mechanical work from little temperature differences. Let’s first look at the primary parts of a Stirling engine to help you understand better how it works.

Primary Components of a Stirling Engine

- Heat Source: The heat source is the driving force behind the Stirling engine’s movement. It’ll heat the air inside the Stirling engine. Then, it’s transferred to the cylinder. But since it’s a closed system, there’s no way for it to escape. So, ensure that your heat source has enough power to keep your engine running at a constant temperature. Stirling engines don’t burn fuel compared to internal combustion engines. They only need a temperature difference between the heat source (where the energy emanates) and the heat sink (where it ends).

- Flywheel: The flywheel is a heavy wheel mounted to a spinning shaft. It conserves angular momentum and reciprocating engines. The flywheel is located on the outer part of the crankshaft, similar to an Internal Combustion Engine. The power piston and the displacer are connected to a flywheel. It stores the power output of the Stirling engine for further transmission.

- Gas: It can be any gas, provided it has a low boiling point to be used in a Stirling engine. It can be hydrogen, helium, or ordinary air. The gas is inside a cylinder, and this cylinder is connected to a piston. As the piston moves back and forth, it pushes the gas into another chamber, where it expands. This way, it pushes the next piston. The gas used should remain in the gaseous state whether it’s heated or cooled. The primary purpose of the gas is to transport heat energy from the heat source to the engine’s heat sink. The heat energy powers the piston that operates the machine.

- Pistons: The piston is a cylindrical component that moves up and down inside the cylinder. This movement is caused by the expansion of gasses inside the engine that forces the piston to move up. The piston acts as a gate for the gas flow. It allows it to enter the cylinder when it moves down. If you have ever seen an air compressor at work, you have seen how a piston can compress air into a cylinder. The same principle is used in Stirling engines, except that gas inside the cylinder gets compressed.

- Heat Exchanger: It’s also known as the regenerator. You can find the heat exchanger between the heat sink and the heat source. Usually, the heat exchanger is made of copper or aluminum because they have high thermal conductivity. The heat exchanger holds heat from the hot gas that goes past it. When the hot gas moves back, it gathers this heat again. The heat can be wasted and lost in the outside air if the Stirling engine doesn’t have a heat exchanger. The regenerator enhances your engine’s power and efficiency. Several Stirling engines have many regenerators.

Now you know the primary parts of a Stirling engine. Here’s how a Stirling engine works.

How A Stirling Engine Works

The external heat source starts when the operator switches on the engine starter. The operator regulates the force via the provided mechanism. Heat transfer begins from the heat source to the cylinder’s hot end when the operator activates the external heat source.

This heat transfer process leads to a temperature increase in the gas molecules ensnared in the hot end of the cylinder. As the gas molecules’ temperature increases, there’s an interference between them. The gas molecules expand inside the cylinder.

It, in turn, increases the pressure on the surface of the piston. This way, the piston is pushed, producing helpful work. A plunger (displacer piston) is joined to a crankshaft. The crankshaft’s movement makes the plunger move between the hot and cold ends of the cylinder.

It also causes an exchange of gasses from the cold end to the hot end of the cylinder and vice versa. The gas at the hot end drives the displacer piston. Then, it transfers the gas into the cylinder’s cold end.

When the hot gas is introduced into the cold end, the cooling device extracts heat from the hot gas and cools it.

Once the gas has cooled, the piston compresses it into the cylinder’s cold end. A cooling device gets rid of excess heat from the gas. Once the compression process is complete, the displacer piston returns the compressed gas to the cylinder’s hot end. Then, the cycle repeats itself.

Point to Note: The Stirling engine doesn’t have an exhaust stroke like other engines. So, it’s eco-friendly and more efficient than an internal combustion engine.

What Are the Different Types of Stirling Engines?

Here are the two primary types of Stirling engines.

- Displacer Type Stirling Engine: A displacer Stirling engine is more like a heat pump than an internal combustion engine. It runs using a displacer and a piston. It also uses the temperature difference between two reservoirs (one hot and one cold) to create energy. Usually, the hot reservoir is heated by burning fuel. The cold reservoir can be air or water. The most basic design uses a sealed cylinder with connecting ports on opposite sides. One side connects to a cold reservoir, while the other side connects to a hot reservoir. There’s also a sealed chamber in the middle. It contains an expanding gas. As long as there’s enough heat differential between these two sides, there will be a motion that drives this engine forward. The displacer type engine is used in Beta and Gamma Stirling engines.

- Two-Piston Type Stirling Engine: The two-piston type Stirling engine is one of the most basic types of Stirling engines. This Stirling engine uses two pistons to compress and decompress air to heat or cool it down. These pistons move in a circular motion. They alternate between heating and cooling with each stroke. A crosshead connected to both pistons moves them back and forth. The movement of these pistons switches the position of the displacer piston between the Stirling engine’s hot end and cold end. It causes a pressure difference between these two ends. The pressure makes them move back and forth. These types of Stirling engines are used in applications where a high power output is needed. They can be used for things like powering heat pumps or even homes.

Where Is a Stirling Engine Used?

Stirling engines have various applications. They work well in machines that generate power continuously. They can also be used as a power source for spacecraft, boats, and even trains. Besides, NASA has developed a Stirling engine used to power their spacecraft.

These engines have many advantages over other engines. They don’t use fossil fuels or radioactive materials to produce energy. Besides, they produce less pollution than gasoline-powered engines. Also, they’re much lighter than conventional internal combustion engines.

Besides space exploration, Stirling engines are also commonly used in agricultural equipment. These machines must be powerful enough to operate large blades or moving parts. These machines don’t need a lot of torque or speed like an automobile needs.

Stirling engines can also be used as refrigerator engines, prime movers, and heat pumps. Besides, they’re used at water pump stations, for solar power generation, and in submarines.

The Stirling engine operates efficiently at low speeds, making it ideal for these applications. The equipment may be stationary most of the time but still needs power when working with heavy loads.

- More efficient compared to steam engines

- Operates quietly

- Need minimal maintenance

- Highly flexible

- It can operate on any heat source available. It includes geothermal, biological, and nuclear sources.

- Ideal for powering appliances in areas with limited fuel supply

- Can operate at low temperatures

- Low emissions, making it eco-friendly

- Simple design and doesn’t have movable parts, making it highly dependable

- Compact size

- Consumes low mechanical power

- Fewer resonations compared to internal combustion engines

- Can run at high speeds with small temperature changes

- It takes a lot of time to start

- Must have large radiators to drive out waste heat

- Heavy due to an extra heat source

- Need an extra external source of heat to heat the operating fluid (gas)

- It doesn’t operate effectively in hot weather

- Expensive compared to other engine types

- It doesn’t operate effectively at high altitudes

- Starting it is challenging during cold weather

- It can only run on direct mechanical power

How to Increase the Stirling Engine’s Efficiency

Stirling engines are known for their high efficiency and quiet operation. But, you can make it more efficient. Here are several ways to do it.

- Increase the Power in the First Stage: The first stage is the compression stage, which converts the heat into mechanical energy. The hot gas generates pressure to push the piston to work in the first stage of the Stirling cycle. The power output of the Stirling engine is higher if the gas pressure in this stage is high. One way of increasing the pressure is to increase the temperature of the gas.

- Reduce Power Consumption in the Third Stage: The piston uses part of the energy produced to compress the gas in the third stage of the cycle. This way, the pressure is reduced in the third stage. The pressure reduction minimizes power consumption. Engine power also increases as a result of this. Another effective method of reducing pressure is cooling the gas.

- Make the Temperature Difference Large: Your Stirling engine will also be more efficient if there’s a large temperature difference between the cold and hot cylinders. You’ll create a large temperature difference by increasing the gas pressure in the first stage and minimizing it in the third stage.

History of the Stirling Engine

The first Stirling engine was used in 1818. It was a pumping appliance used to pump water in a mine. Earlier, there were trials to manufacture an air engine, but the Stirling engine was the first to be used. Robert Stirling and his brother James were the first people to invent it. The name Stirling was not given to the engine immediately after its invention until later on when a Dutch engineer, Rolf Meijer, gave it the name Stirling. It delineated all closed regenerative gas engines.

The Stirling engine was a safer option than the steam engine. The steam engine was risky due to high-pressure boiler explosions. Although this was not the primary purpose of the Stirling engine, it was used as a dependable and safe source of low to medium power.

It was used to pump water and a cooling fan. In the 1970s, the Stirling engine started being used in refrigerators. Several firms used them for central heating systems. The greatest achievement of Stirling engines was the ability to produce green energy.

FAQs

1. Who invented the Stirling engine?

The Stirling engine was invented by Robert Stirling in 1816. He was born in 1790 and later died on June 6, 1878. Robert Stirling was a Scottish clergyman. He used his knowledge of steam engines to design an air-cooled heat engine. It didn’t have the disadvantages of conventional steam engines. From 1818 to 1922, his firm manufactured these engines. The engines pumped water to farms and produced electricity.

2. Why are Stirling engines not used these days?

Stirling engines rely on hot air expansion and compression for their operation. So, they need time to reach operating temperature before producing any helpful power output. It’s not an issue for large stationary applications like water heating or steam production, but it makes them unsuitable for mobile applications, such as automobiles. The Stirling engine doesn’t change its output power fast compared to internal combustion engines.

3. What is special about a Stirling engine?

The Stirling engine uses an external heat source to heat and cool the same fixed amount of gas, rather than using a separate gas supply for each cycle. It reduces the amount of energy needed for operation.

The gas pressure is controlled by removing or adding heat. Removing heat decreases the gas pressure. On the other hand, adding heat increases the gas pressure.

4. Which gas does a Stirling engine use?

Stirling engines are similar to steam engines in that they use a working fluid (liquid or gas) heated by external means. But they differ in using the expansion and contraction of that fluid as opposed to steam pressure. Stirling engines use hydrogen or helium to run. These gasses are used because of their enhanced thermal properties.

5. Why are Stirling engines expensive compared to internal combustion engines?

Stirling engines are more efficient than internal combustion engines, but they are also more expensive. The primary reason is that Stirling engines need more complicated parts than other engines.

One component of the Stirling engine that makes it costly is the heat exchanger. Heat exchangers need special materials that must obtain a high-temperature difference. This temperature difference makes the engine achieve high efficiency.

Conclusion

Stirling engines are fascinating machines. They’re quiet and energy efficient. They work by using the heat differential between the two sides of a piston. That’s it!

Now that you’ve gotten an overview of the theory behind Stirling engines, it’s probably time to think of ways to harness the power of this technology.

Even if you’ve never encountered a Stirling engine before, we are sure you can think of one or two applications where you want to power something with this engine.

- Primary Components of a Stirling Engine

- How Does a Stirling Engine Work?

- What are the Different Types of Stirling Engines?

- Where is a Stirling Engine Used?

- Advantages and Disadvantages of a Stirling Engine

- How to Increase the Stirling Engine’s Efficiency

- History of the Stirling Engine

- When was the Stirling Engine Invented?

- Why are Stirling Engines Not Used These Days?

- What is Special about a Stirling Engine?

- Which Gas does a Stirling Engine Use?

- Why are Stirling Engines Expensive compared to Internal Combustion Engines?

- THERMEX

- NASA SCIENCE

- THE UNIVERSITY OF EDINBURGH

Featured Image Credit: Murt y, Shutterstock

Contents