How Does a Hydraulic Ram Pump Work? Types, Best Uses & FAQs

-

- Last updated:

After realizing the effects of greenhouse gasses on the environment, the whole world has been striving to use green energy solutions. One of the first steps of going green is reducing electricity and fuel consumption by using methods that utilize simple science. One of the most successful solutions is using a hydraulic ram pump.

Also known as a hydram, the hydraulic pump is essentially a cyclical water pump that transfers water from a source to the community using zero external energy. Instead, it utilizes the raw natural power of rapidly moving or falling water to operate.

In this article, we will discuss how hydraulic rams work, where they are used, and the benefits they have to society at large. Keep reading for deeper insight.

How Does the Hydram Work?

As mentioned earlier, the hydraulic ram pump works on a principle called “water hammer”. This simply refers to a wave or a surge of pressure that is created when flowing liquid is made to stop or suddenly change direction. This change in the momentum of the fluid raises its pressure, which raises water to a higher level than it was when it started flowing.

Simply put, the hydram utilizes the water hammer effect to create pressure, thus allowing incoming water that runs the pump to be elevated to a higher point than how the water started flowing.

Usually, water flowing in a pipe has momentum that can resist a sudden change in velocity. When you slowly close a valve in the pipes, you allow the momentum to dissipate, thus reducing the pressure inside the pipes.

However, when you rapidly close the valve in the pipes, you create a shock wave or pressure surge as you stop the flow of water in its tracks. This forces the water back up into the pipe, like a train stopping where single train cars hit the coupling directly in front of them as the brakes are applied.

Therefore, the quicker a valve is closed, the larger the pressure surge produced. Water flowing rapidly will also create a larger shock wave after the valve is closed because inertia is involved in the process. The same is also witnessed when using longer pipes.

The hydraulic ram device relies on non-pressurized water flowing in a pipe from a water source to the drive pipe. This flow is produced by installing the hydram a considerable distance below the water source and connecting the drive pipe from the source to the pump. The only moving parts in a hydraulic ram pump are two check valves.

A Systemic Explanation of How a Hydram Operates

To help you further understand how a hydraulic pump operates, check out our step-by-step explanation.

Water Flows & Pressure Builds

Water flows through the drive pipe and into the waste valve, which is usually initially open. Here, water flows rapidly through the pipe and out through the waste valve1. At a particular point, water will be moving so rapidly in the waste valve that it pushes the flapper in the valve up, then slams it shut.

The water momentum in the pipe may have been considerably higher, but the closure of the valve stops the weight and inertia of the water, thus creating a high-pressure spike at the waste valve that was just closed. This spike in water pressure forces some of the water into the pressure chamber via the check valve.

This process further increases the water pressure, but ever so slightly. The pressure in the pipe also moves away from the waste valve and into the drive pipe at an incredibly fast speed. The water is then released into the drive pipe inlet.

Pressure is Released

When the high-pressure shock wave gets to the drive pipe inlet, a normal pressure wave goes back down the pipe and into the waste valve. The check valve could slightly still be open, but this will depend on the back pressure, thus allowing water to flow into the pressure chamber.

Check Valve Closes

When the normal pressure shock wave returns to the waste valve, a normal pressure wave will go up the drive pipe, consequently lowering the pressure at the valves. This will allow the check valve to close and the waste valve to open.

The Next Cycle Begins

As soon as the low-pressure wave gets into the drive pipe inlet, the normal pressure wave will travel down the drive pipe and to the valves. Elevation at the water source will allow normal water flow to follow the pressure wave as the next cycle begins.

What Are the Different Types of Hydraulic Ram Pumps?

Essentially, there are three main types of hydraulic pumps used in a mobile hydraulic mobile application. These include pistons, gear, and vane. However, other types of hydraulic pumps are available in today’s market. They include dump, clutch, and dry valve pumps used for refuse vehicles.

Each of these hydraulic pumps can either feature a bi-rotational design or a uni-rotational design. Uni-rotational pumps work in one direction shaft rotation, while bi-rotational pumps can operate in either direction.

Main Types of Hydraulic Ram Pumps

1. Gear Pumps

Gear pumps are commonly used in truck-mounted hydraulic systems. Their design features fewer moving parts, is more tolerant to contamination, is easy to service, and is relatively cheap. These types of pumps are also known as positive or fixed displacement pumps.

This simply means that the pumps produce the same flow with each rotation from the pump shaft. Usually, these types of hydraulic pumps get their ratings based on their cubic inch displacement, their maximum pressure rating as well as the limitation of their maximum input speed.

Gear pumps are generally used in hydraulic systems that are open-centered. They usually trap oil between the body of the pump and the two gear teeth. It then transports it around the gear cavity circumference and then later forces it through outlets such as the gear mesh. Behind the wear plates or thrust plates, the pressurized oil will push the plates on the ends of the gear to improve the pump’s efficiency.

- External gears: In external gear pumps, there is only one gear connected to the drive. The driven gear only rotates in the opposite direction so that the wheels of the rotating gear interlock.

- Internal gears: In internal gear pumps, both internal and external gear wheels are present. Once the external gear begins its rotation, some volume will be created between external gear teeth fixed on the gear housing walls and the gear wheel profile, thus allowing liquids to be sucked up once the wheels disengage.

2. Piston Pumps

When you need high operating pressures, piston pumps are the ideal choice. Traditionally, piston pumps can withstand higher pressures when compared to gear pumps featuring comparable displacements. However, piston pumps have higher operating costs, increased complexity, and lower contamination resistance.

Due to their complexities, you may need a service technician or an equipment designer with the necessary skills and knowledge to ensure that your piston pumps operate at optimum levels. This is because they have stricter filtration requirements, more moving parts, and closer tolerances.

Usually, piston pumps are utilized by truck-mounted cranes. However, their applications also extend to tasks such as ice and snow control, where it may be necessary to vary system flow without changing the engine speed.

A piston pump houses a cylinder block that contains pistons that move in and out of the housing. The movement of the pistons sucks oil from the supply port, forcing it through the outlet. The length of a piston’s stroke will be determined by the swashplate angle a piston rides against.

Since the swath plate stays stationary, the cylinder block, which houses the piston, is the one that rotates with the input shaft of the pump. Furthermore, the total volume of the cylinders in the pump will determine its displacement. Variable and fixed displacement designs are available in today’s market.

3. Vane Pumps

Initially, vane pumps were utilized on utility vehicles, including ladders and aerial buckets. However, today, vane pumps are not a common sight on truck-mounted hydraulic systems since the onset of gear pumps.

In a vane pump system, when the input shafts rotate, oil is drawn from between the pump vanes and transported to the outlet side of the pump. This process is like gear pumps but with one distinction: vanes have one set of gears, while gear pumps have two gear sets installed on a rotating cartridge housed in the pump.

When the area surrounding the vanes decreases on the pump outlet side, it increases on the inlet side. This causes the oil to be drawn via the supply port and removed through the outlet as the cartridge of the vane rotates because of the change in the area.

Other Types of Hydraulic Pumps

Clutch Pumps

This is essentially a small displacement gear pump with an electronic clutch that is belt driven, similar to the one found on the air conditioner compressor in a car. This pump is engaged when one flicks on the switch inside the cab of the truck.

These pumps are mostly used when power taken off an aperture of transmission is lacking or inaccessible. Typical applications of clutch pumps include wreckers, aerial bucket trucks, and hay spikes.

Dump Pumps

Dump pumps are the most recognizable hydraulic pumps we have highlighted on our list. As the name suggests, these pumps are mainly used in dumping applications ranging from tandem axle dump trucks to dump trailers.

However, this type of pump is solely designed for installation in dump trucks and is not ideal for other trailer applications such as ejectors and live floor trailers.

Dump pumps are different from traditional gear pumps because they feature in-built pressure relief components, a directional control valve that is three-way, and an integral three-position. This pump is not suitable for continuous application because it features narrow internal paths that can generate excessive heat.

Refuse Pumps

A dry valve is an important piece of equipment in pumps for refuse. In the off mode, these pumps can conserve fuel and can provide full workflow when needed. Their designs may be similar to the standard gear pumps; however, dry valves feature a special kind of valve.

The dry valve is mainly used on refuse equipment because it is crankshaft driven and has a large displacement. The special valve used on these pumps restricts movement while in OFF mode as well as permit movement when in ON mode. Consequently, their horsepower draw tends to be lowered, allowing you to save on fuel when the pump is not in use.

Where Is a Hydraulic Ram Pump Used?

Hydrams are especially useful devices in remote and hilly regions where people live high above the nearest water source. It allows the residents of such areas to save valuable time by reducing the distance they have to travel to get water for irrigation or domestic purposes.

While hydrams can essentially be used in any place with a water flow, the device requires areas with a high-water volume to perform effectively. This is because this type of hydraulic ram pump transfers roughly 10% of the total water flowing through the pump.

In case you live in a mountainous region with a low-volume water source, consider alternatives like a Solar MUS system.

Advantages of Hydraulic Ram Pumps

- These devices do not require a prime mover because they mainly operate themselves.

- They feature a simple design.

- Repair and maintenance costs are significantly lower.

- The expenses for operating hydrams are negligible.

- These systems do not use electricity since they rely on hydropower to run, thus making them pollution free.

- They are reliable and very durable.

- Since hydrams work continuously, they offer a regular output.

- They feature no moving parts.

Disadvantages of Hydraulic Ram Pumps

- Hydrams can only pump 10% of the total water volume received, with the rest going to waste via the waste valve.

- Hydraulic ram pumps cannot pump viscous fluids to a considerable height, hence only used to pump potable or drinking water.

- These devices require a continuous water source supply at a height of not less than 91 cm (3 feet).

- They can be very noisy while being operated on.

- Installation costs can be very high.

- They are only ideal for specific areas.

Frequently Asked Questions (FAQs)

Can a hydraulic ram pump work in a river?

Hydraulic ram pumps are designed to adapt to locations with a limited power source. Since they do not need electricity to run, they can run anytime the river is flowing, and need neither sunshine nor wind to operate.

What is the principle behind a hydraulic ram pump?

Essentially, a hydraulic ram works when the external fluids are simultaneously pumped into either side of a cylinder, thus creating a high-pressure and low-pressure condition inside the cylinder. However, the pressures created will depend on the liquid that the pump is trying to move.

What are hydraulic gear pumps used for?

Gear pumps are mainly used in the petrochemical industry to move pitch, diesel oil, crude oil, lube oil, and other types of fluids. They have applications in the chemical industry in materials such as sodium silicate, acids, plastics, and mixed chemicals, among others.

In addition, gear pumps are used in transporting paint, ink, and resins. The pumps are also utilized in the food industry for transporting adhesives.

What is the pressure of a hydraulic ram pump?

Most gear pump systems have an operating pressure that really goes lower than 50 bars. However, on gear pumps, the maximum pressure they can reach is 250 bar, but the standard pressure is 210 bar.

Piston pumps, on the other hand, work with high pressures and can reach 450 bar. But the standard operating pressure of piston pumps is between 300 and 350 bar, usually in an open circuit kind of piston pump.

Conclusion

As you may have gathered, a hydraulic ram pump encompasses a broad prospect. This device is mainly used to transport water from an inaccessible water source to the homes of communities living in a mountainous region.

Despite transporting only one-tenth of the total water flowing in a stream, it can help residents in a hilly area by reducing the distance and time they have to travel to get access to water for their domestic use.

The initial costs of installing a hydraulic ram pump may be high, but the operating, maintenance, and repair costs are significantly lower, if not negligible.

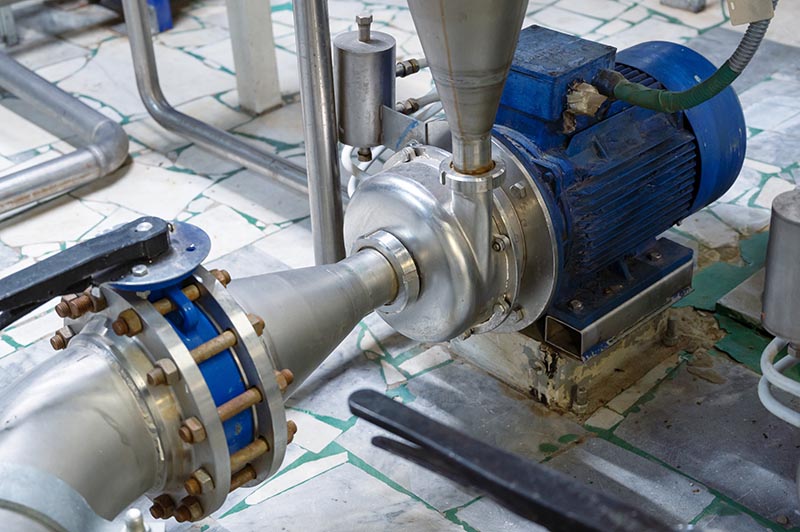

Featured Image Credit: Khoirul yaqin, Shutterstock

Contents