Drywall Screws vs Nails: Types, Benefits & FAQ

-

- Last updated:

Screws and nails may serve the same general purpose, but rarely is there a time when the choice between the two doesn’t matter. Picking the wrong fastener can slow down your project and cause performance issues over time. It violates building codes in many instances, and no matter what, it opens the potential for expensive repairs and safety risks.

Drywall is one area where screws have a clear advantage over nails. Both can work in certain situations, but screws provide a stronger hold with less effort. We’ll compare drywall screws versus nails to give perspective on making the best choice for your next project.

Overview of Drywall Screws

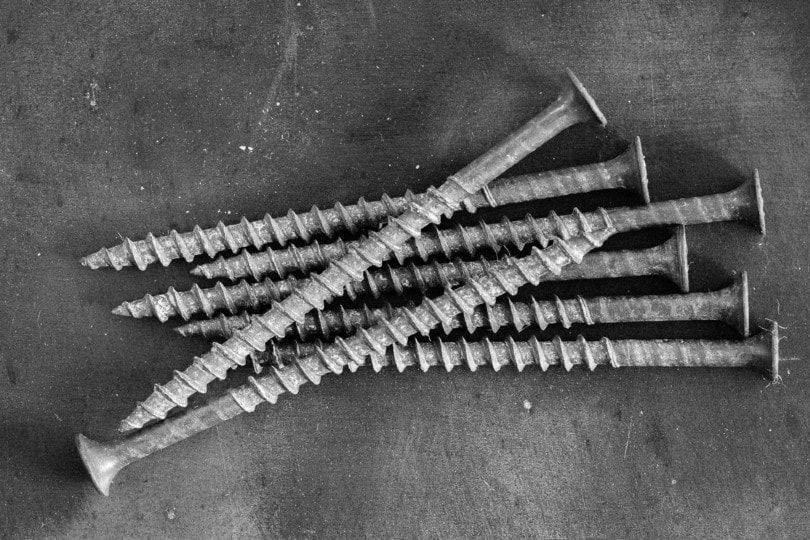

Drywall screws bear a unique form ideal for attaching drywall and hiding the head for a smooth paint application. They are self-tapping, utilizing a sharp point that is easy to stick into drywall for a controlled installation. The Phillip’s head has a bugle shape. It tapers to prevent damage to the fragile gypsum and paper surface layer of the drywall, allowing you to countersink the head flush with the wall and pin it in place.

Most drywall screws have a black phosphate coating. One minor benefit of phosphate is its corrosion resistance, which helps it withstand rusting as the moist joint compound dries on top of it. The primary purpose is to reduce friction as the screw enters the stud. The phosphate coating allows the screw to slide easily and prevents galling, which can cause the screw and stud to adhere to a friction weld, making it difficult to remove.

Types of Drywall Screws

You will typically find drywall screws in #6 or #8 widths and various lengths, generally between 1 ¼ inch and 2 inches, though you can find some screws up to 3 inches long. Longer screws can hold more weight and are often practical when fastening multiple pieces of drywall for added fire resistance and sound dampening. They sometimes feature a bare section between the head and thread to keep the screw from going too far into the drywall.

Alongside the minor range of lengths and thicknesses to match varying drywall and stud profiles, there are two general types of drywall screws — coarse and fine-thread drywall screws.

Coarse-thread screws have a wider gap between the thread than fine-thread screws. The thread you choose will depend on whether you have a metal or wood stud.

Coarse-Thread Drywall Screws

Coarse-thread drywall screws (or “W-type” screws) work for wood studs. The wide thread allows more wood to fill the gap, creating a sturdy hold. The coarse thread also creates a smaller path to follow than a fine thread drywall screw, letting you install it faster.

Fine-Thread Drywall Screws

Fine-thread drywall screws (or “S-type” screws) have a longer thread that spirals in a tight pattern around the screw shaft. These self-threading screws are ideal for holding drywall against metal studs, as they won’t chew through the metal like a coarse-thread screw. They take longer to screw in than coarse-thread screws, and the smaller gap between the threads creates a weaker hold in wood, so it’s best to use fine-thread screws only on metal.

Overview of Nails

Like drywall screws, nails feature a flat head and a sharp point for driving. The shaft is smooth, allowing you to tap them into place with a hammer.

Drywall nails come in the same lengths and widths as drywall screws. They sport a phosphate coating for added rust resistance and friction reduction. A cupped head allows the nail to sink below the drywall’s surface, and it will typically utilize a ring shank design. The minute grooves running down the shaft provide a better grip inside the underlying wood stud.

Why Are Drywall Screws Better Than Nails?

Screws are a better option than nails in nearly every drywall situation. Threading supplies the most tensile strength and produces a tight grip that resists loosening over time and prevents two objects from pulling apart. With the right equipment, drywall screws are also easier to countersink and much faster to install.

In some instances, such as drywalling the ceiling or mounting to metal studs, screws are the only viable choice. No matter what, choosing screws will save you time and provide more attractive, longer-lasting results.

Drywall Screws Provide Better Grip

Tensile strength is crucial to prevent the annoying nail pops that create blatant blemishes on an otherwise smooth surface. As gravity pulls on the drywall, it can gradually wiggle nails out of their holes. The drywall attachment will loosen, and the slightest pressure will expose the nail head. Ceiling drywall can be particularly problematic, as it’s more likely to pull away from the joists and toward the floor.

Drywall Screws Are Easier and Faster to Install

With the proper tools, drywall screws are easier and quicker to insert than nails. You may think a nail gun with drywall nails will speed things up, but the lack of depth control makes them woefully impractical.

When you don’t drive them to the correct depth, your fasteners will either stick above the drywall surface, making them impossible to conceal, or go too deep and rip the paper surface. Maintaining the drywall paper is crucial to keep the panel attached to the stud. Even the tiniest tear around the head can eventually open and ruin the connection, often causing the drywall to pop out and swallow the fastener.

A nail gun may be fast, but it’s not precise, so for drywall nails, the only practical option is to hammer them. With drywall screws, you can feel free to use a powered screw gun. Screw guns typically cost over $100, but they will let you rattle off perfectly set screws every time, sparing you tons of time and aggravation if you install a lot of drywall.

Screw guns feature a Phillips bit that compresses (“dimples”) the wall around the screw to make it easy to cover with mud. Most products have a depth setting that stops the screw from going too far into the drywall. Many guns also take collated screws for extra speed, keeping you from manually reloading the bit.

Use a Regular Drill with a Drywall Bit

If you don’t have the money to blow on a new screw gun, you can turn your regular drill into a drywall drill with a drywall screw setting bit. These Phillips bits have a ring that stops them from going too far into the drywall. Instead, they gently dimple the panel without breaking the paper, leaving a firm hold and a small indentation to smooth over with joint compound. A pack of four drywall bits only costs about $5–$10 at a local hardware store.

Save on Materials

Building codes may vary, but you typically need more nails than screws when installing drywall. Nails generally need a spacing of no more than 8 inches to allow a firm hold on wall studs and no more than 7 inches when installed into ceiling joists. By contrast, you can space drywall screws 16 inches apart on the wall and 12 inches apart on the ceiling. As the project scales up, it becomes even faster and more cost-effective to use screws.

How to Choose the Right Drywall Screws

To choose the appropriate drywall screws for your project, consider the stud material and the thickness of the drywall. The drywall thickness will determine the screw length:

- ¼” Drywall: 1 ¼” screws

- ½” Drywall: 1 ¼”–1 ⅝” screws

- ⅝” Drywall: 1 ⅝”–2” screws

You also need to choose between coarse and fine-thread screws.

Why Does the Screw Thread Matter?

Though more expensive than wood studs, metal studs resist fire damage, mold, rot, and pests, making them ideal in high-risk areas like bathrooms and basements. They take the same general outward shape as wood studs, but galvanized steel studs are hollow on the inside. The metal is wafer-thin, with standard thicknesses around 0.5 mm for non-load-bearing frames and 2 mm for structural supports.

Since the metal is so shallow, a coarse thread screw would rip clean through it and leave a stripped hole. A fine thread screw can create a thread in the sheet metal, giving it something to grip. Both screw types can work for wood studs, but coarse-thread screws will go in faster and create a slightly firmer grip.

Benefits of Drywall Nails

There are two places to avoid using drywall nails—ceilings and metal studs. Ceilings create a downward force that demands tensile strength for holding onto the joists. Meanwhile, metal studs cause all kinds of issues for nails. The reverberating impact of the fastener going into the frame would be immediately problematic, and there would be virtually no grip between the smooth shaft and the thin metal stud.

For a wall, you can use either drywall nails or screws. While screws are still the best option, nails have one minor advantage here—cost. A pack of drywall nails is marginally less expensive than a pack of screws, and if all you have is a hammer, a few bucks, and an urgent need to get this drywall up, then nails are the best choice.

Trying to countersink screws without a dimpling bit on your drill is extremely difficult. You’ll likely poke more than a few holes in your drywall trying to set them. One convenient aspect of a hammer is that you can lightly depress the wall around the nail head without damaging the paper.

Final Verdict

If you can choose between drywall screws and nails, make the easy decision. Drywall screws are faster and simpler to attach, and you won’t have frustrating nail pops and loose panels ruining your flawless installation. Nails will work, but if you have a drill, it only takes a small investment to make your life a lot easier.

Featured Image Credit: (L) pryzmat, Shutterstock | (R) Camera-man, Pixabay

Contents