7 Different Types of Engineered Wood (with Pictures)

-

Pete Ortiz

- Last updated:

Wood is one of the most popular building materials worldwide, enjoying a long and storied history. While not quite as enduring as stone, wood is used to create homes, furniture, flooring, and more. With wood more in demand than ever, advancements in technology have gifted us artificial wood that helps to alleviate environmental concerns.

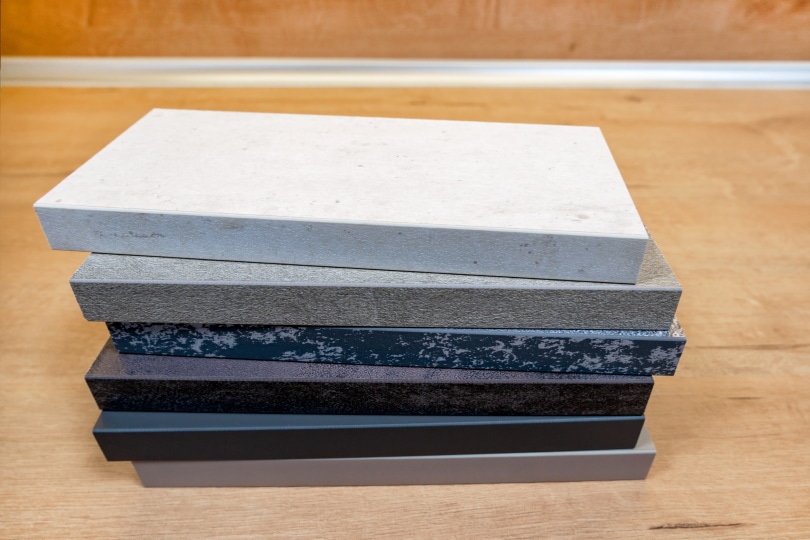

Engineered wood, also known as the manufactured board, is a type of wood created from sawdust, trimming, and other byproduct pieces from traditional lumber processing. These pieces are put together with adhesives, binders, and other materials to create a solid type of wood that’s useful for many of the same applications as traditionally milled wood.

There are numerous types of engineered wood available with their own composition as well as pros and cons. Let’s check out some of the most prevalent types of engineered wood.

The 7 Different Types of Engineered Wood

1. Plywood

Plywood is the first and most well-known engineered wood because it’s so versatile for indoor and outdoor projects alike. Plywood is constructed by cross-laminating wood veneer sheets using water-resistant adhesives combined with heat and pressure.

What makes plywood so versatile as a building material is that it’s constructed with a cross-grain design that lends it a ton of dimensional stability compared to other woods that can collapse or crack along grain patterns.

The main issues with plywood are that it has a rough surface, so it needs to be sealed or finished unless you’re using it as a framing material.

- Very strong

- Durable

- Extremely economical

- Hard to cut because of density

- Has to be finished/sealed

- Not as strong as timber-derived wood

2. High-Density Fiberboard (HDF)

HDF is highly durable wood created from pulped wood waste, chips, and other waste products. The waste is pressed together with resins and adhesives at extremely high temperatures to bind it together into an extremely dense and strong form.

HDF is sometimes preferable to plywood because it’s stronger. Another area where HDF beats plywood is its ability to withstand shrinking and swelling from moisture and temperature changes when properly treated.

HDF is often used as an engineered alternative to hardwood flooring because of its high durability factor, plus it has a smooth surface that makes it easier to cut and paint.

- Moisture-resistant

- More durable than plywood

- Smooth surface

- Doesn’t have a wood grain appearance

- Vulnerable to high heat

3. Particle Board

Particle board is widely known for its trademark chipped appearance. It looks like that because the particle board is quietly literally just a bunch of sawmill trimming, sawdust, and wood chips compressed together with synthetic binders.

Particle board is one of the cheapest engineered woods, which is because it’s not as durable as others like plywood or composite board. It is, however, very cheap and light. For mass-produced furniture that only sees light use, it’s an ideal choice.

- Cheapest engineered wood

- Plentiful

- Lightweight

- Weakest engineered wood

- Wears out more quickly than other woods

- Low moisture-resistance

4. Blockboard

Blockboard is a type of engineered wood created by sandwiching wooden strips together in between layers of wood veneer. You can identify the blockboard because, on the sides, it appears that the board has 3 or 5 similar but distinct layers. Blockboard uses a softwood core, which makes it a great lightweight wood to work with.

Blockboard is better than particle board for multipiece projects because blockboard can hold together with screws very well. Unfortunately, it’s not nearly as strong as plywood is. It makes up for that lack of strength by being easy to cut.

Carpenters hate this wood because the core of the wood has a small gap. When nailing or screwing, your fasteners may not hold at first.

- Holds screws and nails well

- Lightweight

- Strong vertical bearing abilities

- Hard to screw and nail together

- Not as strong as plywood

- Small gaps in the core can be annoying

5. Oriented Strand Board (OSB)

OSB is created by compressing wood flakes and chips together with adhesives at high temperatures in wide machines. The resulting wood is excellent at holding heavy loads, which is why it’s the wood of choice for roof decking, flooring, and other load-bearing jobs.

OSB comes in smooth, sanded versions and rougher unsanded variants, and is available in a weather-resistant form at an increased price. OSB needs to be slightly gapped if used end-to-end because it will shrink and swell like plywood and many types of solid wood.

- Great for load-bearing applications

- Weather-resistant

- Takes longer to get wet than other wood

- Cut edges are not water-resistant

- Dries slowly when wet

- Swells when wet

6. Medium-Density Fiberboard (MDF)

MDF is a composite wood formed of hardwood and softwood scraps, which makes it versatile. This type of engineered wood is usually denser than plywood or OSB, but it has no natural weather resistance and swells when wet.

Because it’s so fine in composition, MDF doesn’t hold nails or screws very well, and they break loose easily. MDF is stronger than particle board and cheaper than plywood, making it a wonderfully cost-effective material for durability.

- High strength

- Smoother than plywood

- Cheap

- Absorbs water and swells

- Easily damaged

- Hard to join with nails and screws

7. Cross-Laminated Timber (CLT)

This is an interesting type of engineered wood that’s made from sheets of timber compressed together perpendicularly. This is easily the strongest wood on the whole list, with a strength comparable to concrete as far as its weight to square foot ratio.

The pros of CLT are that it’s very thick, which makes it a great framing choice when soundproofing and insulation are a priority. The stiffness of CLT makes it unyielding when used as a structural material.

The biggest problem with CLT is that it’s very expensive—more expensive than steel or concrete, in fact. Adding to that, CLT is a pain to run wires and pipes through because it has no natural gaps.

- As strong as concrete

- Excellent insulation

- Does not bend or flex

- Difficult to run wires and pipes through

- More expensive than concrete

- Rarer because it’s not mass-produced

Conclusion

Engineered wood continues to grow in popularity as a cheaper alternative to real wood, and it helps support a form of recycling too. Most engineered wood is less durable than real wood, but it is usually more weather-resistant. Engineered wood is also usually pretty easy to work with, while real wood is expensive and sometimes hard to craft.

Featured Image Credit: Chitaika, Shutterstock

Contents