18 Different Types Of Wood Joints (With Pictures)

-

Pete Ortiz

- Last updated:

Wood joints are used to connect two or more boards together. They can be basic or complex, and you can see them on wooden items like furniture and even the frame of the house, all around you. Below, we have included 18 different types of wood joints, as well as information on when they would each be used. You don’t need to learn them all to be considered a joiner, but

The 18 Different Types of Wood Joints

1. Butt Joint

The first joint on the list is the simplest and arguably the most commonly found. The butt is the name given to the end of a piece of wood, and a butt joint is so called because the butt of one piece sits flush up against another workpiece, at a right angle. The nature of this joint means that adhesive fastening will not usually provide a stable enough joint, so mechanical fastenings, such as screws, are normally used to connect the two pieces and finish the joint. This is seen in picture frames and a lot of types of furniture.

2. Mitered Butt Joint

A mitered butt joint is a little more complicated than a butt joint and refers to the miter saw that is used to cut the wood. Angled cuts are made at the ends of the wood that will be connected. The most common miter joint is a 45° miter, with four of these being used to create a square or rectangular frame. They do offer more strength than a basic butt joint because of the extra surface area, but miter joints also require mechanical fastenings, and can benefit from adhesive, too. Like the basic butt joint, the miter joint is also used in furniture and picture frames.

3. Coped Joint

Corners of rooms and furniture are rarely square, which renders the basic and perfectly mitered butt joint useless. The coped joint leaves one side of the joint square while the other section is cut to slot over the uneven surface. This is commonly used for mouldings and door trims.

4. Dovetail Joint

The dovetail is a very popular joint that creates a strong corner and does not require mechanical fastenings to create a bond. Because the end of the joint tails are wider, the wood effectively locks together. The joint can be achieved by hand, although they can also be machined. The extra pull strength that is afforded to these joints makes them popular in cabinetry and also in drawers.

5. Half-Blind Dovetail

With a dovetail joint, the connection is visible from the end of both pieces of wood, which means that it can be visible at the front of a finished workpiece. The half blind dovetail is similar to that of the dovetail except that the joint is covered by remaining wood.

6. Sliding Dovetail Joint

The sliding dovetail benefits from the dovetail trapezoid shape but rather than a series of pins, it has a single, long trapezoid pin that slides into a trapezoid groove. The joint is invisible when the piece is complete and the design of the pin means that it is very difficult to pull apart.

7. Box Joint

Dovetail joints are effective, efficient, and they look good, except where the joints are intentionally hidden. However, it can be difficult to machine or hand cut the dovetail shape accurately. The box joint works on a similar principle and using a similar design, but rather than trapezoid shapes, it uses rectangular pins and tails. It is easier to craft but doesn’t look quite as elegant as a dovetail and needs gluing to ensure it holds in place.

8. Dowel Joint

Dowel joints are commonly found in self assembly furniture kits. Holes are drilled in both pieces of wood. A dowel is placed inside both holes so that the wood connects and uses the dowel, and some glue, as the fastening.

9. Biscuit Joint

A biscuit joint is similar to a dowel joint except that the pieces of wood have a slot cut in them and, instead of a dowel, the fastening is a small piece of wood that fits that slot. The biscuit is glued in place and when the glue expands, it creates a very secure bond.

10. Finger Joint

Used to connect two pieces of board to make one longer piece of board, this type of joint has slots cut into the ends of both pieces of wood. The slots are longer than in a dovetail or box joint and this gives extra surface area to glue and create a long-lasting bond.

11. Half-Lap Joint

In a half-lap joint, the connecting ends of the pieces of wood are thinned to half their thickness. One piece laps over the other and the two are usually glued together. This isn’t a very strong joint, but it can be visually appealing. Used in framing and furniture making, this type of joint provides uniform thickness around the frame.

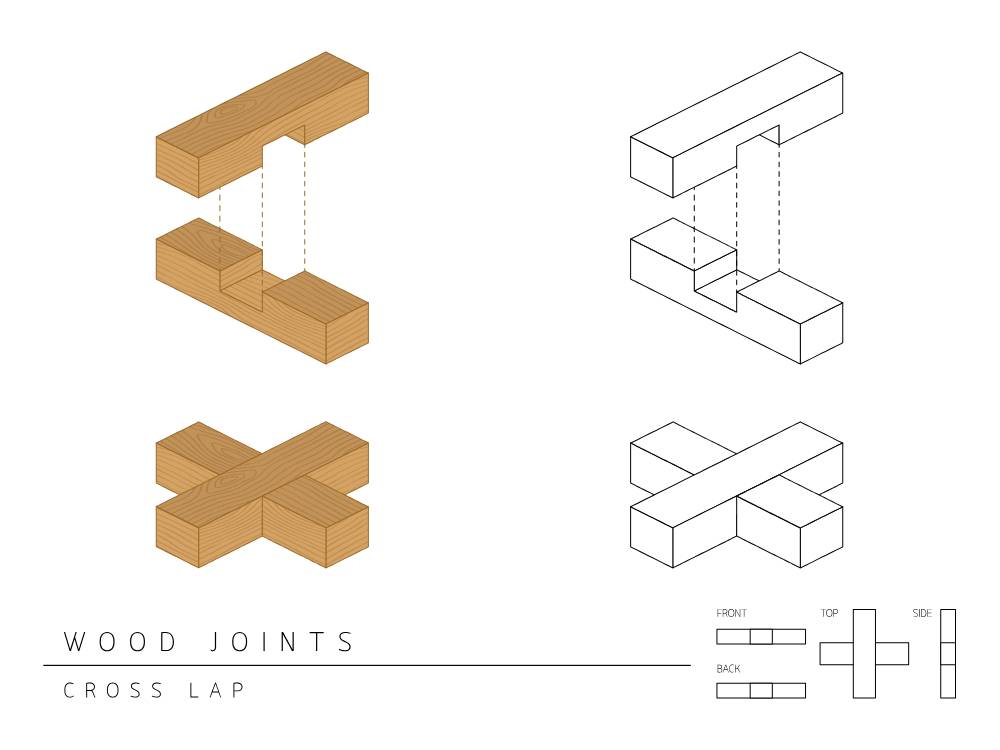

12. Cross-Lap Joint

Lap joints can be made on corners, as in half-lap joints, but the end of one piece of wood can be lapped over the center of another, or two centre pieces can also lap across to crease a cross-lap joint. Again, the big benefit of these joints is the uniformity that is offered in frame thickness.

13. Mortise and Tenon Joint

One of the oldest of all woodworking joints, the mortise and tenon joint has a protruding piece, called the tenon, at the end of one piece of wood and this slides into a corresponding hole on the end of the other piece of wood, called the mortise. The joint is glued for adhesion. It is stronger than a butt joint.

14. Bridle Joint

The bridle joint is similar to a mortise joint except that it has a long edged tenon and a deeper mortise. Also, the mortise can stretch all the way along the end of the piece of wood.

15. Pocket Hole Joint

A pocket-hole joint is a modified butt joint. The two pieces of wood sit together, and are glued together, as they are in a butt joint. However, the pocket hole joint is different because it has pilot holes in both pieces of wood that allow for screws to be fastened. The holes are usually drilled at a shallow angle and further secure the joint.

16. Rabbet Joint

This is another joint that is similar to the basic butt, but offers more strength. The technique allows the back of a cabinet or other piece of furniture to sit perfectly flush against the bottom and sides, giving a cleaner and more precise finish. It is also an easy joint to achieve.

17. Tongue and Groove Joint

The tongue and groove joint is popular when combining two long pieces of wood to create a wider piece. A long tongue is cut down the length of one piece and a corresponding groove is cut into the length of the other. The tongue fits inside the groove, glue is applied, and the pieces sit flush together. This is commonly used in flooring but may also be used in cabinetry and furniture making.

18. Dado Joint

A dado joint is like that of a tongue and groove, except it is cut across a length of board rather than down its length and, rather than using a tongue, the whole end of the piece of wood slots into the groove. This is often used in joining pieces of plywood and pressed wood products.

•You might also like: What is a Transmission Flush (And Do I Need One)?

Conclusion

There are slight variations to many of these types of joints, which means that there are potentially dozens of wood joints that you can learn. Choosing the right one for a woodworking project will help ensure a secure and reliable connection, and it can also have a big impact on the aesthetic appeal of the finished piece, so it is important that you get it right.

Featured Image Credit: Pexels

Contents