10 Concrete Facts and Statistics To Know in 2025

-

Pete Ortiz

- Last updated:

Note: This article’s statistics come from third-party sources and do not represent the opinions of this website.

Ready to dive into some concrete knowledge? If you’re here, you probably want some facts, figures, and statistics on concrete.

Did you know that you can use concrete for building homes, commercial buildings, bridges, and roads? Did you know it’s the most used manufactured material in the world?

The appeal of concrete is its strength, durability, and versatility. With the right mix, it’s possible to create anything. You can create the solid ground on which to build your life, a swimming pool for recreation and play, and even smooth floors on which to dance.

It’s no wonder that concrete has been used for construction for thousands of years. It’s still the number one choice today. In this post, we will focus on the key concrete facts and statistics.

Top 10 Concrete Facts and Statistics

- A concrete mixture comprises 60-75% aggregate, 15% cement and water, and 5-8% air.

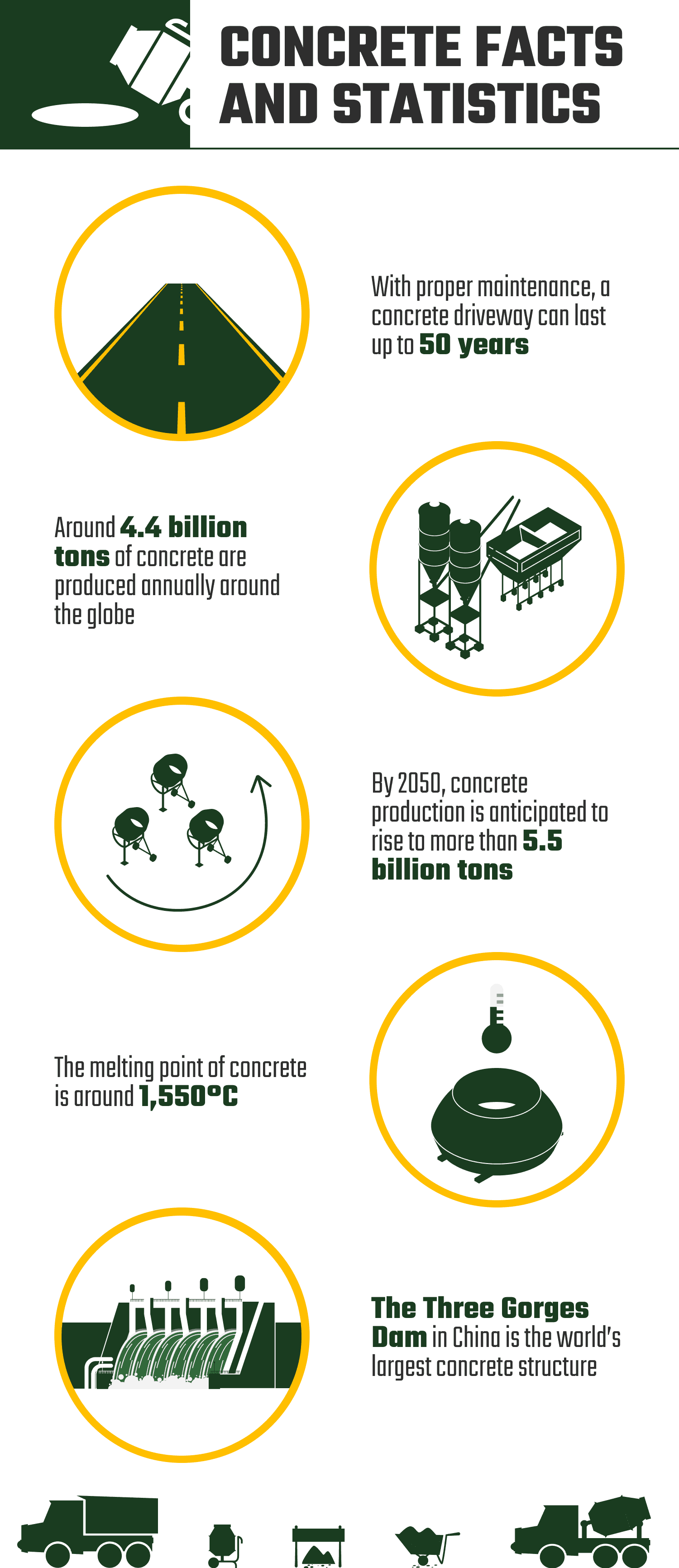

- Unlike seashell, stone, and asphalt, a concrete driveway can last for 25 to 50 years.

- One key ingredient in concrete is cement. More than 4 billion tons of cement are produced annually.

- Around 4.4 billion tons of concrete are produced annually around the globe. By 2050, the figure is anticipated to rise to more than 5.5 billion tons.

- The cost of producing one ton of recycled concrete aggregate is 40% less compared to producing natural concrete aggregate.

- Concrete is one of the most commonly used materials for underwater structures.

- Precast concrete is used in hotels, nursing homes, low and mid-rise apartment buildings, and motels.

- The Three Gorges Dam in China is the world’s largest concrete structure.

- The melting point of concrete is around 1,550 Degrees Celsius.

- Vibration (external or internal) is the most common method of consolidating concrete.

1. A concrete mixture comprises 60-75% aggregate, 15% cement and water, and 5-8% air.

(CEMENT)

Concrete has four key ingredients: aggregate, water, cement, and air. Each ingredient has a specific role to play in the final quality of the concrete.

Aggregates are the large building blocks that constitute concrete. The two most common aggregates used in concrete are gravel and sand. Gravel adds weight, while sand adds strength and helps keep concrete from cracking.

Cement is the binder that holds the aggregate together. It’s added to make concrete strong and stable.

Air is also incorporated into concrete when mixed during the manufacturing process. It allows for easier mixing and pouring of the cement and gravel mixture. Besides making it easier to use, the air keeps concrete from cracking as it dries.

Water serves as a lubricant. It also helps control the rate at which concrete hardens.

2. Unlike seashell, stone, and asphalt, a concrete driveway can last for 25 to 50 years.

(UNIQUE PAVING MATERIALS)

Toughness, longevity, and low maintenance make concrete an excellent option for driveways and walkways. While asphalt and other materials may seem like more affordable options, they need a higher level of maintenance and regular cleaning to ensure proper appearance.

Concrete is strong and durable, making it the ideal material for driveways and walkways. The strength of the concrete also allows you to use less of the material in the overall project, cutting down on costs during installation.

3. One key ingredient in concrete is cement. More than 4 billion tons of cement are produced annually.

(CHATHAM HOUSE)

Cement is a fine powder that’s mixed with water to become paste-like. It holds concrete together. When you mix cement with sand, gravel, and other fine aggregates, it forms concrete.

Cement is often used in construction. It’s crucial in concrete and mortar applications. It binds the components together to create durable and beautiful structures. It makes the concrete strong, which means builders can use it to support buildings and bridges. You can even use concrete to create items as hard as steel!

4. Around 4.4 billion tons of concrete are produced annually around the globe. By 2050, the figure is anticipated to rise to more than 5.5 billion tons.

(CHATHAM HOUSE)

Concrete is one of the most versatile building and construction materials worldwide. It is used on buildings, transit systems such as bridges and tunnels, and in many other aspects of construction.

The global production of concrete is increasing each year. Currently, 4.4 billion tons are produced annually, and this figure is expected to increase to over 5.5 by the year 2050.

5. The cost of producing one ton of recycled concrete aggregate is 40% less compared to producing natural concrete aggregate.

(RESEARCH GATE)

Producing recycled concrete aggregate is cheaper than making natural concrete aggregate. It’s because waste concrete and stone already exist and do not have to be manufactured. The availability of waste materials also helps reduce transportation costs since it doesn’t have to be transported from far. In addition, recycling concrete reduces the amount of waste generated and the environmental impact.

Recycled concrete is available in different forms. They include crushed products ideal for various types of construction projects, such as road bases, sub-base, and asphalt production. Also, fine aggregates are used in general construction projects, such as house footings, driveway slabs, and pathway production.

6. Concrete is one of the most commonly used materials for underwater structures.

(RESEARCH GATE)

Concrete is an ideal material for underwater structures. Its durability and flexibility make it an excellent material for creating piers, seawalls, jetties, and other structures exposed to the elements of water. It is also the most common building material used in commercial diving projects.

Concrete comes in two forms: a stone aggregate and an aggregate of fine particles. The two most commonly used aggregates are limestone and sand. The addition of cement gives concrete strength and durability. Cement contains chemicals that help “glue” the particles together as it hardens in water.

7. Precast concrete is used in hotels, nursing homes, low and mid-rise apartment buildings, and motels.

(DIRECT INDUSTRIAL SUPPLIES)

Precast concrete has various uses in the construction industry. It can be cut and shaped in various designs, making it possible to build a simple structure or one that is highly decorative. The ability to replace damaged pieces when needed also contributes to the long lifespan of precast structures.

There are several advantages to using precast over cast-in-place concrete. Precast panels can be installed fast and easily on-site. It’s because they are manufactured off-site in a controlled environment. On-site assembly is faster than with cast-in-place concrete, where the concrete has to cure before it can be moved.

8. The Three Gorges Dam in China is the world’s largest concrete structure.

(FCS)

The Three Gorges Dam is located on the Yangtze River in China. The reservoir created by the dam stretches for 600 km along China’s east coast.

There are many reasons to be impressed with this engineering marvel apart from being the world’s largest concrete structure. It is also the largest hydroelectric dam in the world. It took more than four years to build it for $22 billion.

This hydroelectric power plant supplies electricity to over 100 million people throughout China’s eastern region. The dam is also a source of water for irrigation, flood control, and recreation.

9. The melting point of concrete is around 1,550 Degrees Celsius.

(RESEARCH GATE)

Concrete has a high melting point. Although it’s technically possible to melt concrete, it needs a high temperature. The chemical composition of the cement and additives in the concrete determine how quickly the material will melt.

There are two ways to test the melting point of concrete. One is the direct approach, and the other is indirect. The direct way involves placing concrete in a furnace and measuring its temperature at intervals.

The indirect approach involves heating a sample in a furnace up to temperatures above 1,550 degrees Celsius. Then, cool it back down to room temperature.

10. Vibration (external or internal) is the most common method of consolidating concrete.

(PRECAST)

Vibration can be applied from outside or passing a machine through the source material.

External vibration is the best option for consolidating concrete. You can rent an external vibrator from most construction equipment suppliers. Also, you can buy it. Unlike internal vibrators, they are not heavy, bulky, and hard to move.

They are also easy to use. External vibrators have a steel bar where you attach the wheel that provides the vibration. You can use them for various purposes, including compacting soil and driving fence posts.

How to Prepare Concrete

Concrete is a composite material. It’s versatile, and you can use it for various building structures, such as foundations, walls, floors, swimming pools, and driveways.

You’ll need about three cubic feet of concrete for every 100 square feet of surface area. Bags of premixed concrete are sold by volume and not by weight. So, check their labels before you buy them.

Concrete is easy to work with but must be prepared well for the best results. No matter what job you’re planning to do with concrete, the first step is to prepare the area well. This way, the concrete will adhere to it.

Preparation involves leveling, compacting, and cleaning the area in a way that will allow the concrete to set well once it’s applied.

Leveling and compacting are often done simultaneously because they are part of preparing a surface for any construction. Besides, concrete contractors usually have special machines that can do both leveling and compacting.

If your project requires only one or the other, you can buy either a machine that levels or one that compacts or get them done by different machines.

Generally, when you level the ground, you want to remove any bumps or dips so that it’s flat. It means removing ground coverings, such as leaves or grass, grading soil underneath it so that it’s level with the surrounding.

Differences Between Cement and Concrete

The key difference between concrete and cement is how they are combined. Concrete is a mixture of cement, sand, and water. Cement comes from limestone and clay, which are ground together.

Sand is also added to make the concrete have a smoother texture. Adding gravel or other materials will give the concrete even more strength.

The aggregate gives the concrete substance weight. Water acts as a binding agent for the cement and other ingredients in concrete. The sand prevents cracks from forming in the concrete by filling in gaps between aggregate pieces.

The other difference between concrete and cement is in their methods of application. Cement can only be applied when it’s in powder form. You must mix it with water to form a thick paste before using it to build.

On the other hand, concrete is poured from a cement mixer truck that has already been mixed with water. So, there’s no need for further preparation.

Frequently Asked Questions on Concrete

1. What machine is used to prepare concrete?

A concrete mixer is a machine that combines cement, water, and other components to produce concrete. This machine is used to prepare concrete (a mixture of cement, gravel, sand, and water).

Construction professionals and homeowners use concrete mixers to prepare concrete for various applications such as building foundations or sidewalks.

Besides a concrete mixer, there are other machines used to prepare concrete, such as grinders, shot blasters, and scrabblers. You can also use a chisel scraper or a scarifier.

(FLOORING TECH)

2. What makes concrete crack?

Concrete cracks due to the shrinkage of the material itself, poor workmanship, or construction issues. In other words, several factors can cause cracks to appear on the concrete surface.

Another reason for concrete cracks is other materials are mixed into the concrete or poured over it. While this may seem harmless, materials such as steel and rubber can cause cracking once they expand or contract with temperature changes.

There are several ways that you can repair a crack in concrete yourself. If the crack is small, you can fill it with a colored joint compound or epoxy putty. These materials will hold the concrete together until it can harden properly. Don’t attempt to repair large cracks or holes by yourself unless you know how to do so.

(ARDEX BUILDING PRODUCTS)

3. How long does concrete take to cure?

Concrete takes 28 days to cure, provided the concrete mix was prepared well. Concrete is a mixture of cement, water, and aggregates (usually sand and gravel). The cement powder must be hydrated (dissolved) in the water completely before you can call it concrete.

The reaction between the cement powder and the water releases heat. That’s why your freshly mixed concrete feels warm or even hot.

Treating your freshly laid concrete with a curing compound will help to ensure that the surface cures evenly and any air bubbles are removed. It helps it become as strong as possible.

•You might also like: Garage Floor Tiles vs. Epoxy: Which Is the Better Option?

(THE CONCRETE NETWORK)

Conclusion

There are few materials as sturdy and versatile as concrete. For that reason, it continues to be used across many industries. The ability of concrete to act as a solid, durable material that can easily be molded into the desired shape and size makes it desirable to use in industrial development.

In this article, we’ve outlined interesting information on concrete. There is a lot that goes into production, from the beginning of the process to the end. Fortunately, once it is set up and poured, you can ride on some of the most durable pavement around.

Concrete is a non-renewable resource. But the production doesn’t cause the same levels of pollution as some other man-made products do. And as you can see, it has many more benefits than just basic construction.

- See Also: Types of Concrete

Featured Image Credit: Nordroden, Shutterstock

Contents