What Are Lag Screws? Uses, Types & Sizes

-

Pete Ortiz

- Last updated:

If you ever do a serious project that involves a lot of wood construction or buy a set of plants to help you build something around your home, there is a high likelihood that you will encounter the need for lag screws. Lag screws are often featured in wood construction, and they are usually called out on plans whenever timbers and beams are involved. If you are unfamiliar with the term lag screw, you might be confused. What is a lag screw? What are they used for? How do they differ from regular screws?

This quick overview will break down everything you need to know about lag screws, including their uses, the different types, typical sizes, and how they differ from regular screws and other similar fasteners. By the end, you will be able to confidently describe the differences between lags and drywall screws without breaking a sweat.

What Are Lag Screws?

What Are Lag Screws?

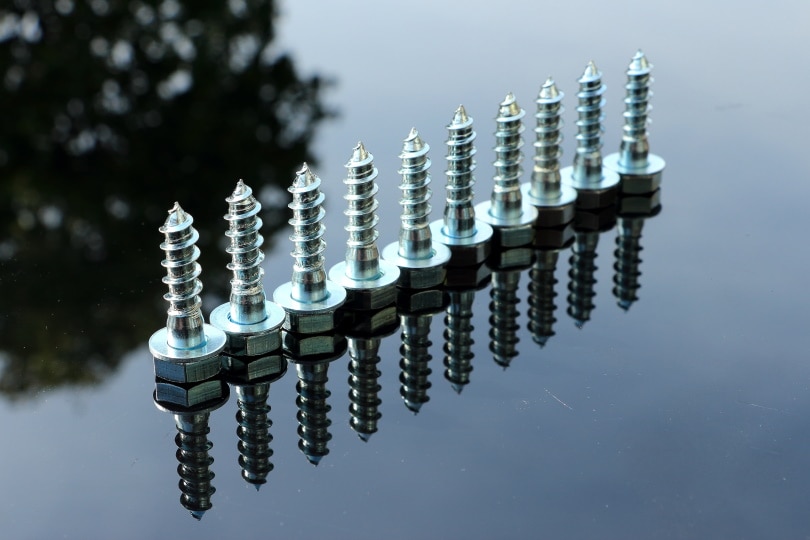

Lag screws are large metal fasteners used for heavy-duty wood construction. Lag screws have hex heads and coarse threading. Lag screws come in a variety of different diameters and lengths. Lag screws are sometimes known as lag bolts. The two terms are interchangeable.

In order to install a lag screw, you must use a pilot bit that is just a bit smaller than the size of your bolt. You need to drill into the prepositioned wood with the pilot bit to make your guide hole before screwing in your lag screws with the appropriate hex head drill. Lag bolts forego the need for a nut or washer because they fit snugly inside of the wood and are designed to bite hard and deep. Once a lag screw is inserted into a piece of timber, it is hard to get them back out, so make sure that your pieces are lined up properly before sinking the bolts in for the final time.

What Are Lag Screws Used For?

Lag screws are primarily used to hold large wooden members together. Large wooden beams are used in many different types of construction from homes, to large decks, docks, pergolas, and more. Any timbers that have a thickness greater than that of a two-by typically call for the use of a lag screw in some capacity.

Any construction that calls for the joining of two large wood beams will often call for some kind of lag bolt to be used to enhance strength and structure. Regular screws are not strong enough to hold two large and heavy pieces of wood together, and lag screws offer additional integrity to keep the beams firmly in place.

Lag screws can also be used to fasten laminated veneer lumber (LVL) to other LVLs or wood beams. LVLs can be incredibly long and have very large widths that could necessitate the use of a lag bolt. LVLs are very common in projects with a long span, and they offer enhanced strength over regular wood. LVLs are often used in home construction and the construction of large buildings like garages and barns.

Different Types of Lag Screws

Lag screws are usually available in three different flavors, zinc, hot dipped galvanized, and stainless steel. Zinc screws are typically used in interior applications. Plain zinc lag bolts are not as common as the other types and are harder to find. Hot dipped galvanized are the most common and the most affordable type of lag bolt. Hot dipped galvanized, also referred to as just galvanized, lag bolts are corrosion resistant and are great for use outside and with pressure treated lumber.

Stainless steel lag screws are by far the most expensive and can be as much as twice the cost of regular galvanized lag screws. Stainless steel bolts are used in high salt environments or when the beams are going to be touching the water. Stainless steel lags are most commonly used in dock and oceanside construction.

Stainless steel lag bolts can run as much as $10 per screw for the largest available sizes. Even the typical stainless steel screws can be as much as $3 to $5 per screw. Regular galvanized lag bolts can be found for less than a dollar per piece in a lot of cases.

| Type | Best Use | Cost | Availability |

| Zinc | Interior | $ | Rare |

| Hot Dipped Galvanized | Exterior or with PT lumber | $ | Common |

| Stainless Steel | Salty air, water, docks | $$$ | Uncommon |

Lag Screw Sizes

One of the things that set lag screws apart from other fasteners is their size. Lag screws are huge, and the largest lag screws are massive compared to regular screws found around the house. The largest lag bolts can measure 3/4 in diameter and be 16 inches long. Bolts that size need serious pilot work done with a drill bit of equal size to ensure that the bolt can penetrate the wood effectively.

Here is a breakdown of some of the common sizes you can find lag screws in.

Nominal Thickness Dimensions (Inches)

- 1/4

- 5/16

- 3/8

- 7/16

- 1/2

- 5/8

- 3/4

Lengths can run anywhere from a single inch all the way up to over a foot long. The thread count on lag bolts is much lower than on other screws. A 3/4 inch lag bolt might only feature 5 threads per inch. Skinnier screws can have as many as 30 threads per inch for comparison.

The combination of different thicknesses and lengths produces dozens of different sizes to choose from. If you are using official plans to do your project, they will call for the exact size of bolts you need (and if the person drawing the plans is good, they will also remind you of what size pilot bit you need as well.)

Generally, you want to give your bolts a lot of room to bite into the final piece of wood. For example, if you are trying to go through a 2×8 into a 3×6, you will likely want to get a lag bolt that is four inches long. Some beams get incredibly thick, as thick as twelve or even sixteen inches, and those need equally long lag screws.

Lag Screws vs. Regular Screws

Lag screws are far larger than a typical screw. Standard screws that most people use on a daily basis include drywall screws, wood screws, metal screws, and masonry screws. The longest of these screws typically only reaches four inches. They come in boxes of either 100 or 500 individual pieces. Regular screws have a variety of different heads on them as well for different applications. Common screw heads include Philips, flathead, star, and hex.

Lag screws are much thicker in diameter, have a coarser thread, and reach much longer lengths. Lag screws can run anywhere from one inch to sixteen inches in length. Lag screws usually start at 1/4 inch in diameter and usually need a pilot hole to start them off because they are so thick. Lag screws also usually only come in hex head configurations as opposed to a multitude of options that you can find with regular screws.

Lag screws are typically sold individually as opposed to in boxes and can be much more expensive than regular screws. Lag screws are used for heavy-duty construction and the fastening of large wooden timbers, while regular screws are great for day-to-day use around the house or in light construction.

- Related Read: When Were Screws Invented? History of the Screw

Lag Screws vs. Carriage Bolts

Another common type of bolt that is used alongside or as opposed to lag screws are carriage bolts. Lag screws and carriage bolts are similar, but they serve very different purposes. Lag screws drill into and catch a large piece of lumber. Carriage bolts are designed to go through a piece of wood and emerge on the other side. For that reason, carriage bolts are also colloquially known as through bolts.

Carriage bolts also hold two pieces of wood together, but they do it using different physical forces. Carriage bolts go through one or multiple pieces of wood and emerge on the other side. The exposed end of the carriage bolt is then fastened with a nut and a washer. Lag screws never emerge from the other side of the wood. They are meant to be sunk into the wood and left in the wood permanently. Carriage bolts can be easily removed once the nut and the washer are taken off. There is no easy way to remove a lag screw once it is sunk.

Like lag screws, carriage bolts can be found in zinc, hot dipped galvanized, and stainless steel finishes. Carriage bolts are also used in the construction of decks, docks, homes, and other similar types of construction as lag bolts.

Since carriage bolts and lag screws are used in the same types of construction featuring large beams, some people get them confused; however, they are very different and often cannot be used interchangeably. Remember, lag bolts stay fastened, and carriage bolts are through bolts. They go through the wood and use a nut and a washer.

In Conclusion

In Conclusion

Lag screws are common in many different types of construction. They are used primarily to fasten two large pieces of wood together. Lag screws come in a large variety of lengths, thicknesses, and finishes that offer a wide array of versatility. The smallest lag bolts can measure just 1/4×1, while the largest screws can be as large as 3/4×16. If you are planning on doing any sort of project that needs wood thicker than two inches, you are guaranteed to run into the need for lag bolts at some point along the way. Now you will know exactly what they are used for and what to look out for when you run into these large screws.

Featured Image Credit: Piqsels

Contents

What Are Lag Screws?

What Are Lag Screws?