What Is a 2-Stroke Engine & How Does It Work

-

- Last updated:

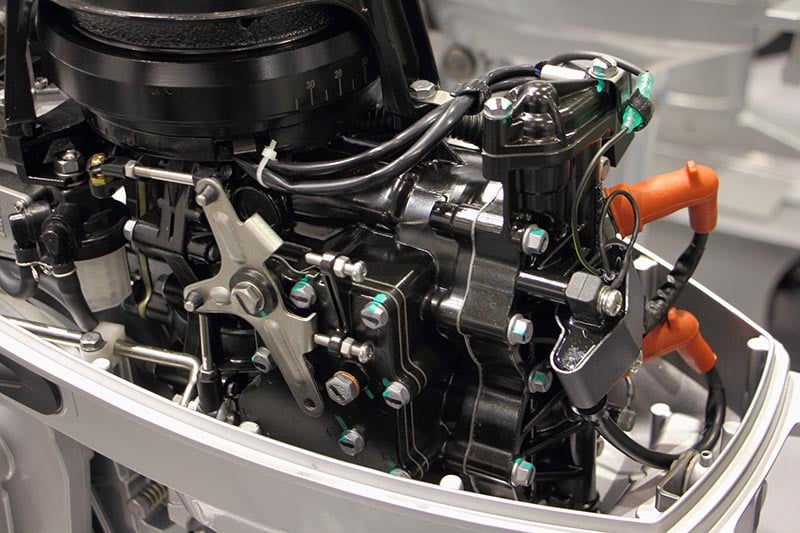

Most vehicles use 4-stroke engines, while most lower-power machines like dirt bikes, motorcycles, jet skis, lawn mowers, and even handheld power tools run on 2-stroke engines. Both engines play the role of converting energy from a fuel into mechanical force and motion.

2-stroke engines finish a single cycle and produce a power stroke in just two strokes of the piston (from TDC to BDC and BDC to TDC). They are lightweight and have a high power-to-weight ratio. Moreover, they offer enhanced mechanical simplicity, which is a significant plus point.

If you are curious about 2-stroke engines and how they work, dive in for an all-rounded guide. We will also discuss the standard applications for this engine and its pros and cons.

2-Stroke Engine: How Does It Work

The 2-stroke engine is also called the 2-stroke cycle engine or the Clerk engine. It is a combustion engine that completes a power cycle in just two strokes of the piston during a single crankshaft revolution.

The 2-stroke engine only has an inlet and exhaust ports. Fresh fuel-air mixtures enter the cylinder through the inlet port, and burnt gases are expelled through the exhaust ports.

By design, the engine eliminates the suction and exhaust stroke typically seen in 4-stroke engines. It only undergoes the compression and expansion stroke, also known as the upward and downward stroke.

Upward Stroke

The upward stroke opens the inlet port, allowing the charge (air-fuel mixture) to enter the crankcase. When the piston moves from BDC (bottom dead center) to TDC (top dead center), the air-fuel mixture is compressed in the cylinder’s combustion chamber, and the spark plug ignites it.

Charge burns to produce heat energy that raises the pressure by hundreds of psi. This pressure pushes the piston down the bore and rotates the crankshaft.

Downward Stroke

During the downward stroke, the piston uncovers the exhaust ports to allow the exhaust gases to escape. However, as it moves toward the BDC position, it gradually exposes different ports.

First, it exposes the exhaust port on the cylinder wall and then uncovers a fresh charge port connected to the crankcase. As the pressure lowers in the cylinder because of the escaping exhaust gases, pressure increases in the crankcase. This allows the fresh air-fuel mixture to flow from the crankcase into the cylinder through the transfer ports.

Both the upward and downward strokes cause one complete revolution of the crankshaft. Once a cycle is complete, the process repeats to provide constant mechanical force and motion.

What Are the Different Types of 2-Stroke Engines?

The 2-stroke engine has been around since 1879. It has evolved immensely over the years to give rise to seven different types of 2-stroke engines. While these engines function under similar principles, they differ in their mechanical details and how they introduce charge into the cylinder and scavenge and expel exhaust gases.

1. Piston-Controlled Engines

The Piston Port 2-stroke engine has the most straightforward design that does not feature valves. It has a configuration where charge enters the engine through an intake port behind the piston.

The air-fuel mixture flows into the crankcase and is pushed into the cylinder through the transfer ports. The piston controls all functions by covering and uncovering different ports as it travels upward or downward through the cylinder.

2. Rotary Inlet Valve Engines

The simplicity of the piston-controlled inlet engine design is commendable.

However, the design offers a short induction period and lower power output. The rotary inlet valve design was a revolutionary invention that allowed the cleaner running of 2-stroke engines. This design also ensures plenty of low-end torque and generally enhanced performance.

Rotary inlet valve 2-stroke engines feature a disk at the end of the crankshaft. The disk has a cutout section that lines up to open or close the crankcase when it spins. During the intake phase, the piston moves upward, and the disk spins, allowing the charge to enter the crankcase.

When the piston reaches TDC, the disk spins again to close the opening and end the intake phase.

3. Reed Inlet Valve Engines

The reed valve design is a high-performance version of the typical 2-stroke engine.

In older and less powerful 2-stroke engines, the suction-compression stroke (upward movement of the piston) causes a sudden drop of pressure in the crankcase. This allows the suction of fresh charge into the combustion chamber during the work-exhaust stroke (downward movement of the piston).

While the old configuration works fine, it delivers less power because part of the fresh charge is pushed into the carburetor from the crankcase. Reed inlet valve engines address this concern by featuring a one-way reed valve between the carburetor and the crankcase.

The valve prevents the fresh mixture from flowing back into the carburetor.

Compared to older 2-stroke engines, reed inlet valve engines offer better reloading of the combustion chamber. Consistent delivery of fresh air-fuel mixture ensures generally improved power output. Reed inlet valve 2-stroke engines can enhance the overall performance of marine onboard engines and motorcycles.

4. Stepped Piston Engine

The stepped piston engines have lower exhaust emissions and better fuel economy. They are also more durable than standard 2-stroke engines and feature three compartments for compression, power, and the crankcase.

The unique configuration of the stepped piston engine allows fresh charge to be compressed in the compression compartment. It is then pushed into the crankcase compartment before expulsion. The stepped piston engine is a new concept mainly available for ultra-small cars and aircraft.

5. Cross-Flow Scavenging Engines

Scavenging refers to the process of expelling exhaust gasses from the cylinder. Once combustion of the air-fuel mixture occurs, the exhaust gas produced escapes through the exhaust ports, and the cylinder is replenished with fresh charge. Incomplete scavenging poses the risk of poor combustion.

Cross-flow scavenging engines feature transfer and exhaust ports on the opposite sides of the cylinder. The charged air is directed upwards, pushing exhaust gas down the opposite side, where it escapes through the exhaust ports.

The cross-flow scavenging engine designs are outdated today, thanks to better versions that allow more superficial and efficient scavenging.

6. Loop Scavenging Engines

The loop scavenging design offers more precisely shaped and positioned transfer ports. This ensures a more efficient flow of air-fuel mixture into the combustion chamber. The efficiency of the process ensures good combustion of the fuel inside the cylinder and assists in adequately cooling the cylinder, valves, and piston.

In the loop scavenging engines, charge air goes over the piston crown to form a loop. The air follows the curvature throughout the combustion chamber, and the exhaust gases are deflected downward. They are then expelled through the exhaust port.

The loop prevents fresh charge from traveling directly to the exhaust port and being removed before proper combustion occurs.

7. Uniflow Scavenging Engines

Compared to 4-stroke engines, 2-stroke engines have less time for scavenging. The uniflow scavenging design improves combustion efficiency by ensuring air flows in only one direction.

The charge air enters the cylinder from the lower end which is controlled by the piston. Exhaust gases are expelled through exhaust exits controlled by the piston or an exhaust valve.

Because charge air travels straight up through the length of the cylinder, this design offers the highest scavenging efficiency compared to cross-flow and loop scavenging.

What Are the Applications of a 2-Stroke Engine?

2-stroke engines are ideal for light-duty applications. They are commonly used in landscaping appliances, off-road motorbikes, chainsaws, generators and small automobiles like mopeds, scooters and small watercrafts.

- Easy to start

- Compact and lightweight

- Enhanced mechanical simplicity and efficiency

- Higher power-to-weight ratio

- Low maintenance cost

- Simple design makes repairs cheaper

- Reduced fuel economy (less miles per gallon)

- Greater consumption of lubricating oil

- More emissions and noise pollution

- Not as durable as a 4-stroke engine

A Quick Reference Guide: 2-Stroke vs 4-Stroke Engines

- Simple design, less parts, more affordable

- Fast, more powerful, less durable

- Lightweight

- Best for smaller applications like dirt bikes

- More torque at a higher RPM

- Loud with a high-pitched “buzzing” sound

- Complex design, more parts, more expensive

- Less powerful, more durable

- Nearly twice heavier

- Ideal for any application that requires an engine

- Higher torque at lower RPM

- Relatively quiet

FAQs

2-stroke engines have numerous perks that make them ideal for chainsaws, boat motors and dirt bikes commonly used for trail riding. Here is more information about these fast and powerful engines.

Is Using 2-stroke Engines Legally Prohibited?

Using 2-stroke engines is legal, although these engines produce high emissions. Therefore, federal air pollution laws regulate their use in specific applications. For instance, cars no longer come featuring 2-stroke engines. Even so, you can use the engine to power your dirt bikes, lawnmowers and other small-scale propulsion applications.

Why Do Automobiles Use 4-Stroke Engines Instead of 2-Stroke Engines?

2-stroke engines are lighter than 4-stroke engines, yet they produce nearly double as much power. However, they are not commonly used to power automobiles because they wear out faster and are not as fuel efficient as 4-stroke engines. They are also quite noisy and produce terrible emissions. Their higher carbon footprint makes them only ideal for smaller machines.

What Is a Stroke?

A stroke is one complete travel of the piston from TDC (top dead center) to BDC (bottom dead center) and vice versa. In 2-stroke engines, the piston makes two movements along the cylinder to complete one power cycle. The lower number of movements compared to a 4-stroke engine makes 2-stroke engines faster.

Will Using Regular Oil Damage My 2-Stroke Engine?

Oil offers crucial lubrication that reduces friction and cools the cylinder. For a 2-stroke engine to function as expected, it needs a unique premixed solution of fuel and oil. Furthermore, the oil used must be of thinner viscosity to avoid damaging your engine.

Can I Use a 2-Stroke Engine on My Snow Blower?

2-stroke engines are perfect for small scales propulsion applications and even better for snow blowers and snowmobiles. Specifically, the 2-stroke petrol engine is pretty dependable in cold temperatures.

Final Thoughts

2-stroke engines are the leaner, faster and more powerful cousins of the 4-stroke engines.

Their design allows greater power output and more instantaneous delivery. However, these engines have high emissions and low fuel economy, making them less environmentally friendly.

In a wrap, the 4-stroke engine is the king of cars. On the other hand, the 2-stroke engine is best for small and lightweight applications like motorbikes. If you want an engine with fewer moving parts and a straightforward mechanical system, the 2-stroke engine is your best bet!

Featured Image Credit: ilmarinfoto, Shutterstock

Contents