What Is a Rotary Engine? Parts, Differences, & FAQ

-

Pete Ortiz

- Last updated:

There are different types of engines used to run automobiles and other machines. The two most common engine types are piston and rotary engines. Piston engines (reciprocating engines) are the most common. So, have you ever heard of a rotary engine? Well, we are here to tell you everything about rotary engines.

The rotary engine is a unique and fascinating piece of engineering. It’s a type of internal combustion engine that uses a triangular rotor. The rotor is the defining feature of a rotary engine.

The triangular rotor also has three curved arms, with an eccentric shaft that makes it spin fast. The movement of the eccentric shaft is converted to rotary motion using a set of cam lobes that sit on top of the eccentric shaft. The lobe position determines the angle of rotation and valve timing.

In this article, we will cover the basic concept of what a rotary engine is and how it works. We’ll also compare rotary engines to piston engines. So, keep reading!

How Does a Rotary Engine Work?

You may have heard of rotary or Wankel engines, but you may not know how they work. Rotary engines are unique to other internal combustion engines. Rather than vertical, with a piston moving up and down, like a regular car, the engine is horizontal.

A rotary engine is sometimes known as a Wankel rotary or a Wankel engine. It’s because the idea of a rotary engine was conceived and developed by Dr. Felix Wankel, a German mechanical engineer and inventor.

Before we explain how the rotary engine works, it’s crucial to look at the parts of the engine first.

Parts of a Rotary Engine

A rotary engine has three primary parts (a housing, a rotor, and an output shaft).

- The Housing: The housing is a crucial part of a rotary engine. It’s the chamber that contains all the other parts. It serves as a protective casing for the rotary engine. Also, the housing has an almost oval shape. The rotor’s three tips stay in contact with the chamber’s wall. This way, it creates three sealed volumes of gases.

- The Rotor: A rotor is the part of an engine that moves around as it turns. It has three convex faces that serve as pistons. Every face comes with a pocket that augments the engine’s displacement. This way, it increases room for fuel/air mixture.

- The Output Shaft: It connects the rotating assembly to the transmission and driveshaft in your car. Usually, it’s made of steel and can be solid or hollow. The hollow shaft allows for the use of planetary gears that help reduce vibrations and make for smoother gear shifting.

Back to How a Rotary Engine Works…

A rotary engine works by spinning a triangular rotor within a housing. The rotor has an eccentric weight attached to the shaft that rotates it. The engine’s housing is fixed in place. As the rotor spins, it pushes air into the housing and then compresses it.

This process continues until all the air in the housing is compressed. Then, the rotor moves up, sucking in more air and pushing out some of the previously compressed air. Each compression stroke takes place in less than half a second. It allows for high-revving performance.

Let’s look at the four strokes of a rotary engine to give you a better understanding of how it works.

The Four Strokes of the Rotary Engine

Four strokes go into the operation of a rotary engine. Each stroke is crucial to ensuring that the engine works properly and efficiently.

- Intake: The intake is the first phase of a four-stroke rotary engine. This is when the fuel enters the rotary engine through an intake port that opens as the rotor turns. During this stroke, the rotating lobes suck in fuel and air. The intake valve opens and closes as one lobe rotates into contact with it. It means there is no need for a camshaft or rocker arms to operate the valves because they are opened and closed mechanically, not hydraulically, like in most engines.

- Compression: Once the air or fuel is drawn into the combustion chamber, it’s compressed to create a high pressure for ignition. In a regular four-stroke engine, this occurs after the power valve opens and before ignition occurs. But, in a rotary engine, it only occurs once during rotor rotation. This compression stroke lasts only a fraction of a second—enough time for fuel to be injected into the combustion chamber and ignited by spark plugs located near each rotor tip. There are no pistons in a rotary engine. Instead, constant revolution inside an enclosed chamber causes compression and expansion of gases. A rotor spins around in an oval-shaped space between two flat plates called seals. As the rotor rotates inside this space, it compresses and expands gases as pistons do in conventional motors.

- Combustion: Combustion in a rotary engine takes place when the rotor reaches near TDC (Top Dead Center). Fuel mixes with the air as the rotor passes over each combustion chamber. Then, it ignites due to pressure from compression occurring just before ignition. The process of burning is called combustion. Then, the flame front moves down through the cylinder head. It pushes out exhaust gases through an exhaust port on the other side of the combustion chamber. Then, it returns to its original position for another cycle.

- Exhaust: The exhaust stroke is the fourth and last stroke of a four-stroke engine. It is when the fumes from combustion are forced out of the motor’s exhaust port. It’s done by the movement of the rotor. It opens up ports on the side of the head. Then, it pushes out exhaust gases through them. All your car’s waste gases are pushed out through an exhaust pipe at high temperatures.

Where Is a Rotary Engine Used?

Rotary engines are used in a lot of different machines. Rotary engines were first used in aircraft. The Wankel engine is lighter than a piston engine. Besides, it produces more power per unit displacement than a conventional piston engine. As such, it has been used in aircraft manufacture, although its use has declined due to poor fuel economy.

The engine is also used in automotive and marine applications globally. The most famous automobile manufactured using the rotary engine is the Mazda RX-7.

These days, the Wankel rotary engine manufactures speed boats and airplanes. Usually, rotary engines are ideal in applications that need low weight and high power.

Rotary engines are not as common in automobiles as they once were. This is due to their inherent disadvantages compared to standard reciprocating piston engines.

- Low operating cost

- The engine speed is high, so it doesn’t need the overdrive

- A high power-to-weight ratio

- Balancing it is easier because it has fewer parts

- Inexpensive

- High volumetric effectiveness

- More compact compared to reciprocating engines

- Lightweight

- Small size

- Easy construction, so it’s ideal for mass-production

- Consumes more engine oil compared to piston engines

- Consumes more fuel at low speeds

- Reduced torque values

- The engine’s braking effect is significantly less

- Spark plugs in older ignition systems require frequent replacement

- Older designs have sealing problems

- High engine speed necessitates speed reduction in the gearbox

What Are the Differences Between Rotary and Piston Engines?

It’s crucial to compare a rotary to a piston engine. With this, you can identify the differences between the two engines. A crucial thing to remember is that the two are different, although they accomplish the same tasks in different ways.

- Operation: The primary difference between a rotary engine and a reciprocating engine (piston engine) is how they work. The pistons in a piston engine carry out intake, compression, combustion, and exhaust in one cylinder. On the other hand, a rotary engine comes with four separate chambers. Each performs a particular task (intake, compression, combustion, or exhaust). Another difference is that a rotary engine doesn’t use pistons to compress air and fuel. Instead, it uses a triangular-shaped rotor that looks like a spinning cogwheel.

- Number of Moving Parts: A rotary engine comes with fewer moving components compared to a four-stroke reciprocating engine. There are three moving parts in a Wankel engine (the output shaft and two rotors). On the flip side, a reciprocating engine has many moving components. They include valves, rockers, camshafts, crankshafts, valve springs, and rods. The fewer moving parts in a rotary engine make it suitable for aircraft manufacturers.

- Engine Size: Usually, the rotary engine is smaller than the piston engine. So, it takes up less space in the vehicle. The rotary engine can also be mounted horizontally, making it easier to fit into various types of automobiles. Besides, rotary engines are lighter and more compact compared to piston engines of the same capacity. It makes them more suited to smaller vehicles such as motorcycles or scooters. These smaller vehicles have limited space for engine components.

- Speed: Rotary engines are known for their high revolutions per minute (rpm), while piston engines have lower rpm. Due to this, rotary engines are used in high-end sports cars or other vehicles that need to go fast. Piston engines are better suited for low-speed applications such as trucks and buses. They can produce more torque at lower speeds than rotary engines.

- Power: Rotary engines are more powerful. Their ability to spin at high speeds makes them more efficient at turning energy into power. Piston engines need more fuel to produce the same power as a rotary engine does with less fuel. The reason is that more steps are involved in producing power from each stroke.

- Smooth Power Delivery: Rotary engines offer smoother power delivery than piston engines. They don’t have reciprocating pistons that cause vibrations when they move up and down. In a piston engine, the pistons move up and down to push the crankshaft that turns the drive shaft. In a rotary engine, the rotors spin and pressurize gas to force it out of ports on the sides of the engine. It creates power over time rather than in one big burst as you get from a piston engine. It also makes rotary engines ideal for sports cars where you want smooth acceleration and torque at all times. Rotary engines are less desirable for trucks or heavy machinery. Usually, these vehicles need more torque at lower speeds.

FAQs

FAQs

What are the similarities between rotary engines and reciprocating engines?

Both are internal combustion engines. The two engine types operate on the four-stroke cycle. Similar to a rotary engine, a piston engine depends on a recurring pattern. The pattern in the two engines is the intake, compression, combustion, and exhaust.

Why does a rotary engine have two spark plugs?

The second spark plug fires the air-fuel mixture into the chamber at the right time to make it burn efficiently. Since a rotary engine has no valves, the engine doesn’t go back and forth between two different combustion chambers.

The engine can only run in one direction. So, it needs two sparks at different points of its rotation. Also, the flame can spread slowly because the combustion chamber is long. So, one spark plug won’t be enough.

What type of oil does a rotary engine use?

The rotary engine has no valves like an ordinary gasoline engine. Thus, it uses special semi-synthetic engine oil. Synthetic oils have special properties that make them ideal for rotary engines-they are thin enough to flow easily through tiny passages.

Conclusion

The rotary engine is an intriguing innovation. It can change the way we view engines. It doesn’t rely on pistons, which are integral to all internal combustion engines. It uses the rotational power of the triangular motor to run.

It’s the same as a piston engine, except it has a few unique properties that make it stand out from other engines. It can achieve high values of power output. Piston engines cannot accomplish this.

Ultimately, the rotary engine is a fascinating piece of machinery. If you can appreciate the engineering behind it, you might also enjoy why it works as well as it does. You’ll also understand why Mazda was successful with it in the first place.

- How Does a Rotary Engine Work?

- Components of a Rotary Engine

- The Four Strokes of the Rotary Engine

- Where is a Rotary Engine Used?

- Advantages and Disadvantages of a Rotary Engine

- Reasons why there was no mass production of the Rotary Engine

- What are the Differences between a Rotary and a Piston Engine?

- What are the Similarities between a Rotary engine and a Reciprocating Engine?

- Why Does a Rotary Engine have Two Spark Plugs?

- What Type of Oil Does a Rotary Engine Use?

- SCIHI

- US CENTENNIAL OF FLIGHT COMMISSION

- FAA

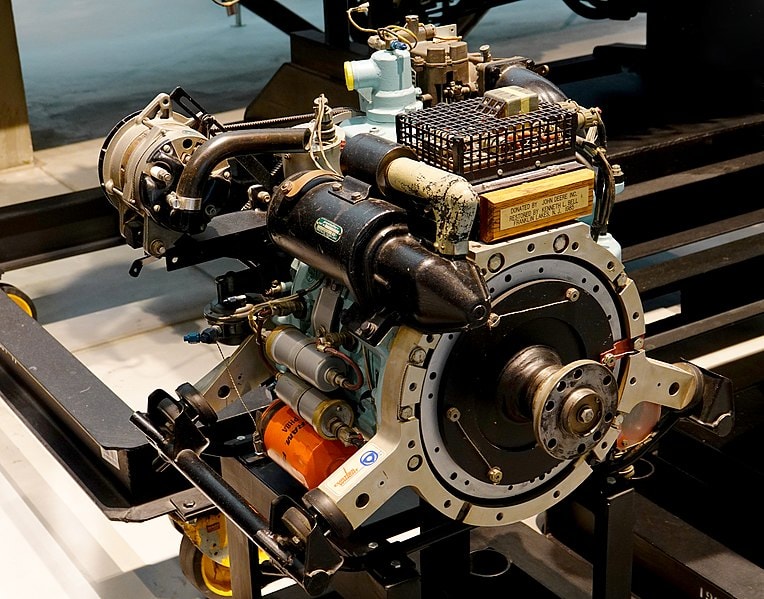

Featured Image Credit: Wankel RC2-60 Rotary Engine (Image Credit: Sanjay Acharya, Wikimedia Commons CC SA 4.0 International)

Contents