What is the Best Wood for Subwoofer Boxes?

-

- Last updated:

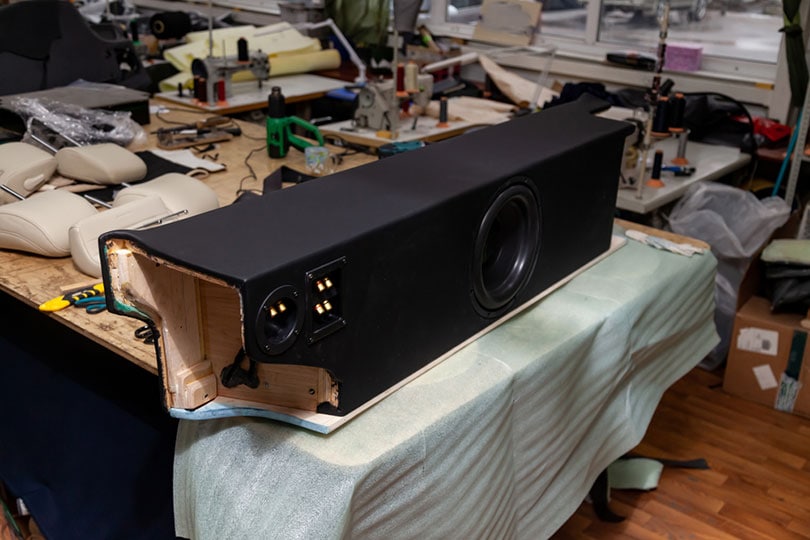

If you’re an avid music fan, you probably know how important a subwoofer is. No matter how great the tweeters sound, without a proper sub, there will never be enough bass. And for the low frequencies to “pop,” you’ll need a premium-quality wood box. That’s right: the housing plays a huge role in shaping the sound of the bass frequencies, directing them to the front. It minimizes distortion and boosts the sound quality, not to mention protects the sub.

So, the big question here is what is the right wood type for the box? Should you go with MDF, or maybe plywood? What’s the difference between oak and pine, and should particle boards even be considered? We’ve got all the answers right here!

To make the choice easier for you, we broke our list down into two categories: hardwood and softwood, each including three wood types. Alright, let’s see what we’re working with!

The Best Wood for Subwoofer Boxes

This term is used to describe wood from dicot trees. These include beech, oak, and birch, to name a few. Hardwoods are the product of deciduous trees that can be distinguished by flowers and fruits; plus, they have broad leaves. Thanks to the complex structure and multitude of vessels, hardwood is sturdier and, well, harder than softwood. However, with so many trees in both groups, there can be lots of variations.

On average, hardwood is pretty expensive but tends to last longer. Strength, easy maintenance, and an extended lifespan; that’s what makes it so popular in construction. It is also in great demand for flooring and furniture, which makes it a perfect choice for subwoofer boxes. Lack of flexibility can be an issue, though, along with above-average weight.

1. Baltic Birch Plywood (Hardwood)

| Wood Type | Hardwood |

| Density | 680–760 kg/m3 |

| Weight | 48 lbs |

| Durability/Strength | High |

Dense, durable, and incredibly resistant to distortion/warping, Baltic birch plywood is, in many ways, the best option on the table. It does an excellent job of housing and protecting the subwoofer and keeps vibrations to a minimum. As a result, you get excellent acoustic performance: strong, punchy bass with no booming tones whatsoever. Built using a unique method in Russia and the Baltic states, this plywood looks amazing untreated.

That’s right: you won’t have to spend extra money on a finishing product. It does get a “royal” gloss when painted, though. And what about the downsides, you might ask? Well, this plywood isn’t particularly cheap, compared to other types. But, if you’re ready to invest in a premium-quality material, it will be money well spent. Baltic birch is incredibly versatile and stable, thanks to the thicker-than-average veneers.

- Highly resistant to warping

- Superb audio component protection

- Looks great both treated and untreated

- A bit on the expensive side

2. Marine-Grade Plywood (Regular Plywood)

Should you really pick Baltic birch over regular birch plywood? What’s the big difference between these two? Well, regular plywood tends to have softwood/filler plies in the center. In contrast, in Baltic birch plywood, the individual plies are much thinner. In simpler terms, more plies sit on top of each other for a given thickness, which means stiffer, more durable plywood for your subwoofer box.

On top of that, Baltic birch is great at screw holding because it doesn’t have voids like some softwood materials do. For woodworking, this is a huge pro.

| Wood Type | Hardwood |

| Density | 672–800 kg/m3 |

| Weight | 50 lbs |

| Durability/Strength | High |

This next type of plywood is even denser than Baltic birch, which automatically means it’s highly resistant to weather elements. You won’t have to worry about temperature fluctuations if you decide to craft the box using marine-grade plywood. Humidity/moisture won’t be an issue either, because this wood is water-resistant and doesn’t swell (which can be a big problem for wood). Stability is a part of the deal as well.

That equals superb audio quality and strong, believable bass response. Add zero resonance inside of the housing, and you’ll see why marine-grade plywood is a worthy pick for a subwoofer box. Originally, this plywood was used by the army to build boats. So, longevity and durability are not a problem here. The only minor con has to do with the edges: they’re quite rough and might require treatment like sanding.

- Easily handles environmental factors

- Water-resistant: doesn’t swell

- Keeps resonance to a minimum

- A bit rough on the edges

3. Oakwood

| Wood Type | Hardwood |

| Density | 593–897 kg/m3 |

| Weight | 45 lbs |

| Durability/Strength | Moderate/High |

This right here is one of the longest living trees on the planet (up to 400 years). Brown-colored, it typically grows in areas with cold climates and is widely used in construction and furniture. As for oak plywood, it’s a great material for subwoofer housing. First, it is sturdy and, just like the tree, has an extended lifespan, which is exactly what we’re looking for. Next, it is very flexible, treatable, and easy to work with.

Even if you’re not a seasoned vet, oak won’t take much time or effort to turn into a box for your sub. Another big pro: it easily handles burning sunlight. Yes, UV rays are known to damage some types of wood, but that won’t be an issue with oakwood. The natural, “expensive” texture is even more reason to pick it over the competition. Do keep in mind, though, that it tends to slightly alter the audio tone.

It’s nothing major, of course, and you won’t even notice it.

- Sturdy, long-lasting material

- Flexible and pliable by nature

- Strong against sunlight (UV rays)

- Tends to change the woofer sound a bit

4. Pinewood (Softwood)

Softwoods aren’t as long-lasting or dense as hardwoods, but they’re more affordable and (generally speaking) more flexible. Easily manipulated, they take less effort and skill to shape to your liking. Softwoods also tend to be lighter (with MDF being an exception to the rule). Plus, they’re fast growers, which should explain the lower cost. As a building material for subwoofer boxes, softwoods can be an excellent choice.

Thanks to their natural acoustic characteristics and non-resonant properties, they do a wonderful job of enhancing the audio frequencies generated by the sub.

| Wood Type | Softwood |

| Density | 352-849 kg/m3 |

| Weight | 37 lbs |

| Durability/Strength | High |

As a coniferous tree, pinewood has an extended strength/durability. Density is above average as well, depending on the species. The first thing that sets it apart from all the other woods on the list is the weight (only 37 pounds). More importantly, it’s one of the cheapest softwood options on the market, and it will be almost perfect for a subwoofer box. We say almost because flexibility isn’t pine’s strong suit.

It’s still manageable, especially if you have the right tools, just not as versatile as oak. Now, pinewood is a natural sound absorbent. That means you’ll get a pure, well-pronounced low-end with no coloration or tone adjustment. Nice and thick, it also benefits greatly from some basic treatment. Finally, pine plywood is incredibly resistant to rot and decay and takes paint well. It serves for many years (if not decades) and keeps the woofer well-protected.

- Available at a very affordable price

- An excellent sound absorbent

- Practically immune to decay and rot

- Not very flexible

5. MDF

| Wood Type | Softwood |

| Density | 600–800 kg/m3 |

| Weight | 58 lbs |

| Durability/Strength | Low/ Moderate |

Many experts in the field swear by MDF (medium-density fiberboard), and for good reasons. Its biggest advantage over other types of wood is class-leading flexibility. Shaping it doesn’t take any expensive tools or equipment. Does that mean it’s easy to break? No, not at all: while durability isn’t market-leading, density is very high.

So, if you’re looking for a material that keeps vibration at bay and minimizes noise, this could be it. Medium-density fiberboard is made from recycled wood particles and is known to enhance low frequencies, helping them cut through a busy track full of mids and highs. By amplifying the audio level via extra thickness, MDF makes the woofer output clear and pleasant to the ear.

One thing to remember is that it’s quite heavy (up to 58 pounds). This can be a minor inconvenience at first. But, once you’re done with the box and find a spot for it, that won’t even be an issue anymore.

- Very easy to shape to your liking

- Minimizes resonance and vibration

- Enhanced the sound of the woofer

- The heaviest wood on the list

6. Particle Board

| Wood Type | Softwood |

| Density | 590–800 kg/m3 |

| Weight | 41 lbs |

| Durability/Strength | Low |

AKA the chipboard, the particle board is another popular construction material that we can use to build a subwoofer box. Particleboards aren’t crafted from one single wood. Instead, they’re made of scraps of different materials (types of wood). So, yes, they’re similar to MDF. Unfortunately, this isn’t a particularly strong or durable material. Furthermore, it can’t handle moisture/humidity properly.

On the bright side, particle boards are low-maintenance and very smooth—no painting, finishing, or staining will be required. In addition, they’re lightweight and maintain low vibration levels. Their biggest pro: advanced acoustic properties. Therefore, if you want your woofer box to be equally sturdy and sonically rich, you could use particle boards for the rear panels and MDF or Baltic birch plywood for the rest of the enclosure.

- Smooth and sleek surface

- Doesn’t distort or dent easily

- Requires minimal maintenance

- Weak against moisture

Choosing the Right Wood for Woofer Boxes: Step-by-Step Guide

Wood is the best material for crafting a subwoofer box—this has been proven countless times in thousands of different projects. However, not all wood types out there are suitable for this type of work. Some are thin, brittle, and weak against weather elements. Yes, there are lots of aspects to consider before you commit, and in this short, yet informative guide, we’ll talk about it all in great detail.

Durability, Density, and Thickness

Time spares nothing, which is why durability has to be the top priority. Compared to metal, plastic, and other materials, wood is more susceptible to peaks in temperature, humidity, and atmospheric pressure. So, the only way to see whether a certain wood type is strong against these factors or not is to check the durability and density. That way, you can ensure a long, trouble-free life for the subwoofer box.

And what about thickness—what’s the right choice here? We recommend going with ⅝ inches. This is an optimal thickness that makes the enclosure thick enough to withstand the test of time while still being lightweight and (relatively) easy to carry around. If you’re going with MDF, ¾ inches will also do. And if the subwoofer is smaller than average, ½ inches can work as well.

Weight Comes Next

This one’s self-explanatory: the heavier the housing, the harder it will be to move the woofer around. Working with heavy wood tends to be a bit challenging, too, especially if you’re not a seasoned carpenter. At the same time, the wood needs to be strong enough to easily hold the audio components of the sub and prevent vibration and shaking. Now, you’ll probably only have to move the woofer once; so, don’t even give this much thought.

Dimensions Follow

All you need to do here is make sure the wood is large enough for crafting panels for the box. Working with one single wood panel is ten times easier and more enjoyable than having to “glue” several pieces together for each side. Take a minute to figure out the exact length that you need for each side of the subwoofer box and go from there.

Flexibility/Ease of Use

Making a subwoofer box requires expertise, the right set of tools, and sleight of hands. That’s why the wood has to be flexible and easy to shape to your liking. As mentioned in the reviews, pinewood isn’t particularly flexible, but it’s still a great choice for a subwoofer box. And if you want a truly pliable wood material, go with MDF.

What about Tone/Resonance?

Sound clarity is one of the defining aspects that sets poor-quality wood from a premium material. To achieve that, you need to make sure vibrations and jitter in the box are next to zero. How do you do that, though? The answer is simple: density. Generally speaking, the higher the density, the more satisfying the tone will be to our ears. And that makes Baltic birch and marine-grade plywood an optimal choice.

Warping Resistance

Last but not least we’ve got warping. Regarding wood materials, warping describes heavy distortion under the impact of environmental factors, mainly temperature and moisture. This doesn’t happen overnight, of course, but let’s just say that subwoofer boxes aren’t cheap, and it would be best if you think about this before spending your hard-earned money on a material with low resistance.

Over time, distortion caused by extremely hot or cold temps and elevated humidity will, most certainly, affect the quality of the sound, making it dull, weak, and not-at-all punchy.

Conclusion

There’s no shortage of subwoofers on the market. However, most of them sound average at best. As we learned today, the reason is low-quality boxes. Fiberglass, Sonotube, or polycarbonate simply don’t cut it, but to keep the price low, manufacturers usually go with fiberglass or other cheap stuff. That’s exactly why audiophiles around the world are getting into hand-made premium wood boxes these days.

They bring the sound forward and make the low frequencies nice and rich, with a deep growl. We just checked out the six best wood materials for a subwoofer enclosure. They all have different densities, weight, durability, and weather resistance properties. Still can’t seem to make a choice? Then go back to our reviews and pay extra attention to the pros and cons. Stay safe and enjoy your punchy bass!

Featured Image Credit: Aleksandr Kondratov, Shutterstock

Contents