Can You Cut Metal With a Miter Saw? Important Facts & FAQ

-

Pete Ortiz

- Last updated:

In your DIYer adventures, you’ll likely come to a project where you need to make an angled cut on metal. The first choice for an accurate cut would be the miter saw, the standard for mitered and beveled woodworking. But while you can use a miter saw to cut light metal, it will be crucial to use the right blade to prevent mistakes, damage, and personal injury.

Miter saws are powerful and versatile, but they are typically not meant to cut metal. If you find yourself in a situation where your equipment stands between you and a finished project, we’ll explain how you can successfully cut metal with a miter saw.

Can You Cut Metal with a Miter Saw?

Can You Cut Metal with a Miter Saw?

You can cut metal with a miter saw, but your blade choice is crucial. A miter saw makes accurate miter and bevel cuts in wood. It’s not the best choice for cutting through metal, and if you have a regular need for it, you should invest in a chop saw.

Though expensive and less versatile than a miter saw, a chop saw is the preferred shop tool for cutting metal. These powerful saws typically use abrasive metal discs, usually 12–15 inches wide, to cut through various ferrous and non-ferrous metals.

A chop saw is the ideal choice for metal because it operates at a lower RPM, typically at least half the speed of a miter saw. Cutting metal produces a lot of heat, and heat increases with the cutting speed. The added friction can cause the metal to expand, causing the blade to bind and potentially damage the equipment or the metal piece.

The other issue with the miter saw is the exposed motor housing, which doesn’t have protection from metal debris. Swarf, the minute metal particles, can get into the saw and damage the components. A higher RPM saw is also more likely to kick up sparks alongside fine bits of metal.

Types of Metal-Cutting Blades

If you need to use your miter saw to cut metal, buying the correct blade is vital. The blade will tell you if it works for ferrous metals (those containing iron), such as steel or cast iron, or non-ferrous metals, such as aluminum and copper. Non-ferrous metals are softer and more forgiving to cut.

A diamond blade will give you the best results when you match it to the type of metal you need to cut. You can also use a carbide-tipped saw blade for many soft metals. You generally want to use a strong disc with a high tooth count to reduce wear on the individual teeth, cut slower and reduce heat, and provide the smoothest cut possible. Smaller teeth also help prevent hang-ups.

What to Consider When Cutting Metal with a Miter Saw

Once you have the correct blade rated for your miter saw speed and the material you are working on, you can set to work with the occasional metal cutting project. Cutting metal can be dangerous, and the risks increase when using an imperfect tool like a miter saw. Follows these tips to stay safe while cutting metal:

- Wear proper eyewear, ear covers, and heavy-duty gloves to protect yourself from flying sparks, metal chips, shards, and sharp metal edges

- Ensure the guard and blade are secure and in good condition, and the cutting area is clear

- Secure the saw and the material you are cutting with a clamp

- Protect intakes, filters, and other openings in the motor casing from metal shards by placing a cloth over them

- Use a wood backer to support thin-walled or tubular metal, prevent the blade from catching and distorting, and stop shards from flying

- Apply lubricant to the blade to reduce wear

- Let the freshly cut metal cool down before handling it

It’s essential to follow the manufacturer’s directions on proper use with any new saw blade. Always get the blade up to full speed before bringing it down. Slowly but firmly press it through the metal, letting the blade do the work. Turn the machine off, and wait for the disc to stop before raising it.

What Is Better for Cutting Metal Than a Miter Saw?

A chop saw is the best investment if you make a lot of metal cuts. It doesn’t have the same range of movement as a miter saw, but the slower RPMs and larger discs are ideal for cutting metal.

For on-site metal cutting, you can use an angle grinder, reciprocating saw, oscillating saw, or a small rotary tool. With an appropriate abrasive disc or a diamond or carbide-tipped blade, these can handle ferrous and non-ferrous metals. A circular saw can also be a powerful tool on the job for ripping sheet metal or cross-cutting pipes.

Our Recommendations for Cutting Metal with a Miter Saw in 2025

Freud Diablo D1080N Saw Blade — Best Overall

The Diablo D1080N Non-Ferrous Metal & Plastic blade is a long-lasting miter saw blade for cutting brass, copper, and aluminum. The triple chip grind blade design and high-density carbide construction maintain the blade’s integrity, keeping the cuts smooth and burr-free. With its thin kerf, non-stick coating, and built-in shock resistance, it delivers optimal efficiency, comfort, and precision through numerous uses.

- Micro grain titanium carbide construction offers enduring performance

- Thin kerf allows for more accurate, efficient cuts

- Perm-Shield non-stick coating prevents overheating and gumming from non-ferrous metal

- Not for use on ferrous metal

- Needs lubricant

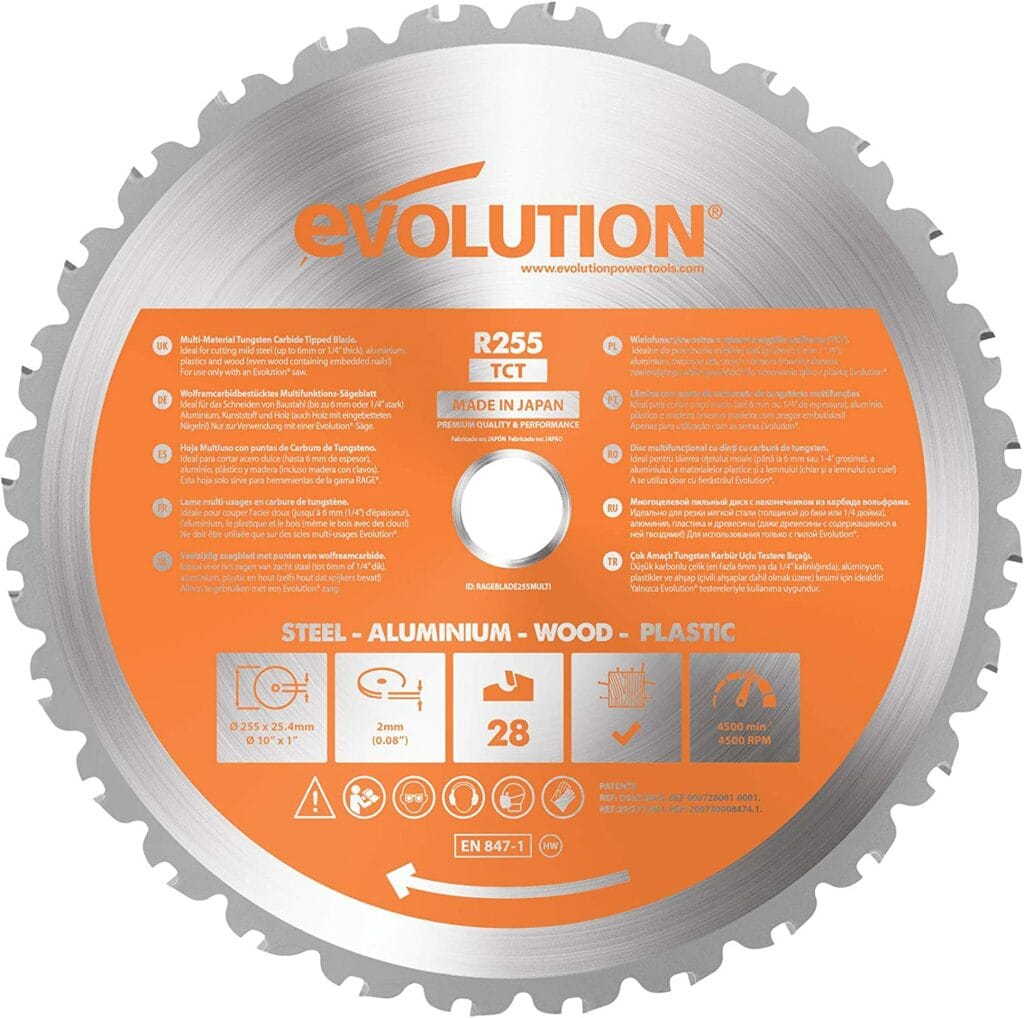

Evolution RAGEBLADE255MULTI — Best Value

Evolution is a leading brand in blade engineering, and the RAGEBLADE255MULTI is a prime example of a unique design that delivers premium results. The thin kerf and heavy-duty carbide teeth prolong the blade’s life, reduce heat resistance, and provide accurate, clean cuts. Stout construction and clever blade design allow you to cut through wood, plastic, mild steel, and non-ferrous metals like butter.

- Relatively inexpensive

- Multipurpose blade works on wood with nails and metal

- Extra-thin kerf offers precision

- Teeth can quickly go blunt in tough metal

- May kick back during use

Conclusion

Conclusion

If you have a one-off metal-cutting task, investing in an expensive chop saw is hardly worthwhile. Although it isn’t the best tool for regular use, your versatile miter saw can handle minor cuts with a diamond or carbide-tipped blade. It shouldn’t be your go-to tool for cutting metal, but by following these tips and carefully choosing the appropriate blade for your machine, you’ll have no problem getting the accurate cuts you need to move your project along.

Featured Image Credit: Aleksei Kariukin, Shutterstock

Contents

Can You Cut Metal with a Miter Saw?

Can You Cut Metal with a Miter Saw?