What Is a Band Saw? Pros, Cons & Types

-

Shea Cummings

- Last updated:

A band saw falls into the “essential tool” category for any serious woodworker. When making strange or unique cuts, these saws have incredible versatility. While several saws can make similar cuts, none really compare to the ease of use of a band saw.

If you are wondering if a band saw is the right choice for the next addition to your woodworking shop, this guide will provide all the information on what a band saw is and its best applications.

How Does it Work?

Simply put, a band saw consists of a ribbon-like metal band with teeth. On most models, this band constantly rotates between two wheels. The platform that you place the material you’re cutting on moves up and down. So, the amount of exposed blade is determined by how thick the material is.

Because of the small size of the cutting band, you can perform very intricate cuts. And you’re able to be very precise because you have full control of the material you’re cutting on the platform. For example, because of the blade’s flexibility, you can make perfect curved or round cuts.

There are several types of blades that we will get into in a little bit more detail below when we discuss where a band saw is used. But one thing to keep in mind when looking at them is the different configurations. These configurations are determined by how many teeth the blade has—called teeth per inch (TPI).

What are the Different Types of Band Saw?

There are various band saws available that are suited for different applications:

General Application Band Saw

Usually, one band saw can cut metal and wood. However, in most cases, you’ll need to change the blade. Because a metal one will not cut wood very well and vice versa. Also, some blades have teeth on both sides of the band so that you can cut in both directions. These are typically found in an industrial setting where heavy-duty cutting is happening.

Vertical Band Saw

Vertical band saws are usually large, floor-mounted saws. The blade is powered by a motor and belt usually, and the speed can be adjusted depending on what you’re trying to cut. A vertical band saw is sometimes called a contour saw because of its effectiveness at contouring.

Horizontal Band Saw

The horizontal version is also usually a floor-mounted saw. The only real difference is that the blade turned horizontally. A horizontal band saw cuts down into the material instead of holding the material and working it around the blade. It is useful for cutting large pieces of material like chunks of wood or metal piping.

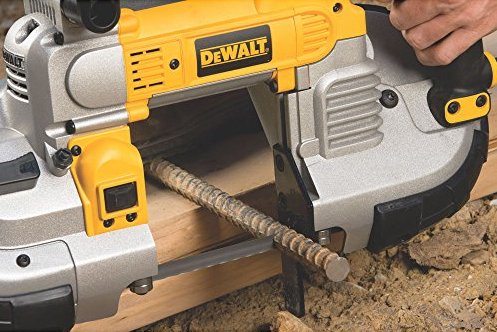

Portable Band Saw

There are some smaller and more manageable band saws that are portable and have their own stands, or you can get some that are even smaller and handheld. These are popular for working on the job site. For example, plumbers will often use a handheld band saw for trimming PVC or metal pipes to size.

Benchtop Band Saw

Sometimes a less expensive option, if you do not need a full-sized, floor-mounted band saw, is a benchtop band saw. Exactly as the name implies, it will mount on your workbench. These saws are available in both horizontal and vertical configurations. Some models are even comparable in power to the big, floor-mounted saw.

Where is a Band Saw Used?

Band saws are common in many different trades and jobs. Here are a few of the most common applications:

- Woodworkers: Making unique and precise cuts on various types of wood.

- Electricians: Cutting large cables or conduit piping.

- Plumbers: Trimming plumbing pipes and PVC.

- Millworkers: Cutting and trimming large pieces of metal to size.

- Machinists: Contouring and shaping metal and other materials to create things.

The beautiful thing about band saws is how versatile they are. Most times, all you need to do is switch out the blade, and you can do a different job with the saw.

Advantages of a Band Saw

There are several powerful advantages when it comes to band saw use. Keep in mind just because it’s an advantage doesn’t mean that a band saw is the only tool that can do the job, but in many cases, it’s the best or easiest tool to use.

Better Cuts

In many cases—especially with fine woodworking where everything is about the details—a band saw will make a faster and more precise cut. For example, a jigsaw can do many cuts that a band saw can do. But the band saw will be a straighter and cleaner cut because the blade can’t wander. And you’ll also be able to make the same cut as the jigsaw way quicker.

Less Waste

A band saw’s blade is much thinner than a table saw or circular saw. So, with each cut, there’s a little bit less waste. A couple of sixteenths may not seem like a lot, but for large pieces of materials, this might add up to needing to start a new piece for one final cut.

Safety

Because a band saw has a minimal amount of blade showing, they are a very safe tool. Of course, they are still a powerful tool that needs proper training and safety precautions. But overall, your chances of serious injury are lower than a table saw or jigsaw, for example.

Versatility

A significant pro to a band saw—as we’ve discussed—is their extreme versatility. A band saw will cut wood, metal, PVC, and many other materials with the right blade. That’s not to say that other saws can’t cut multiple materials, but the versatility is a bonus with the rest of the advantages.

Disadvantages of a Band Saw

For all the bonuses of using a band saw, they have their limitations. There aren’t a lot of disadvantages to using a band saw, however, the few they have are severe and particular. So, in some cases, you’ll find that a band saw is not the right tool for the job.

Size of the Material

Because of a band saw’s design, they are limited in the size of the material they can cut. Different models have different adjustments, but if your band saw only opens up 10 inches, the maximum size of material you can cut is just under 10 inches.

Not Ideal for Straight Cuts

If you need long straight cuts (also called rips), a table saw or a circular saw with a guide are your best bets. A band saw just isn’t designed to make long rips.

- Related Read: 9 Interesting Band Saw Facts

Frequently Asked Questions

Are band saws and scrolls saws the same?

Both of these saws are very similar in appearance and function. However, a scroll saw has a smaller blade and is designed for very intricate work. That’s not to say that a band saw can’t do intricate work, but this is the primary use for a scroll saw.

Does the amount of teeth on the blade matter?

The more teeth the blade has, the finer the cut it will make, but the slower it cuts. You’ll want a blade with a high TPI configuration if you’re doing fine woodworking. This will produce cuts that require much less sanding to finish.

Do I need a special blade to cut plastic or PVC?

If you usually cut wood and you need to cut plastic, most wood blades will cut plastic just fine. The same goes with most metal blades. However, you’ll probably have to clean out the blade more often when cutting plastic because it gets all gunked up with melted plastic.

Conclusion

Band saws are super handy tools. If you’re entering into the trades or you’re a passionate DIY woodworker, the investment is worth considering. Keep in mind that even though they are extremely versatile, there are still jobs they aren’t suited to work on.

Featured Image Credit: Benedek Alpar, Shutterstock

Contents