6 Best Cold Saws – Reviews & Buyer’s Guide 2025

-

- Last updated:

Cold saws are designed to cut through metal. It’s what they live for. They’re an alternative to abrasive chop saws, and we find them much more pleasant to use.

What’s the difference? Abrasive chop saws cut by means of a sharpened disc spinning at high speeds rather than using a toothed blade. If you’ve ever used an abrasive saw, you’ll know they create more sparks than a welding torch. Although that’s a fun adrenaline rush the first few times, you end up craving a tool that’ll do the job with less fuss.

Enter the cold saw. You’re probably here because you like the idea of a toothed metal-cutting saw, which avoids sparks and makes cleaner cuts by applying a steady stream of coolant. If you want to buy a cold saw, our reviews are here to help you. We’ve tested six cold saws to decide which we like best and which could be the one for you. After the list, read on to catch our Buyer’s Guide for cold saw first-timers.

A Quick Comparison (updated in 2025)

| Rating | Image | Product | Details | |

|---|---|---|---|---|

Best Overall

|

|

DeWalt DW872 Cold Saw |

|

CHECK PRICE |

|

|

Makita LC1230 Cold Saw |

|

CHECK PRICE |

Best Value

|

|

Baileigh Manual Circular Cold Saw |

|

CHECK PRICE |

|

Premium Choice

|

|

Grizzly Industrial 10″ Cold Saw |

|

CHECK PRICE |

|

|

|

Evolution EVOSAW380 Cold Saw |

|

CHECK PRICE |

The 6 Best Cold Saws:

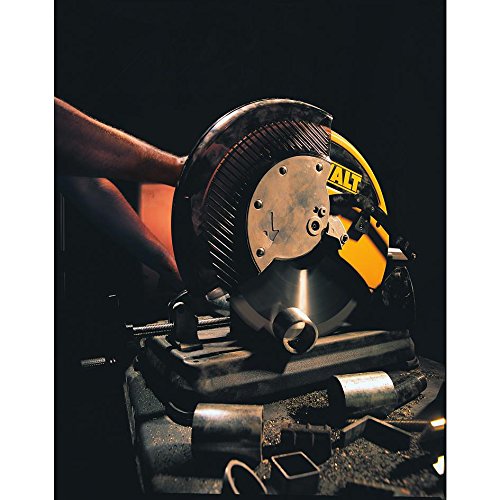

1. DeWalt DW872 Cold Saw – Best Overall

The DW872 14-inch cold saw is a versatile metal cutter that slices through any material quickly and precisely. It’s ready to go right out of the box, with a 14-inch, 70-toothed, carbide-tipped blade that’s one of the few factory blades you’ll never want to replace. It cuts up to four times faster than a chop saw, yet cuts will still be cool when completed.

It’s a heavy, reliable saw that can last many years with proper maintenance. Our favorite thing about the DW872 is how cleanly it cuts; it leaves a flat plane on the metal every time but requires minimal burr cleanup afterward.

The only issues we have relate to the base, where DeWalt made questionable design choices. Getting smaller workpieces to rest comfortably on the corrugated base can be hard, and the user-friendly clamp is somewhat weak. You might want an extra clamp to keep smaller pipes more stable. Overall, we think this is the best cold saw on the market right now.

- Clean cuts

- High-quality blade

- Very little prep work or cleanup per cut

- Faster than a chop saw

- Cuts are cool right after finishing

- Lasts for years

- Corrugated base

- Clamp lacks strength

2. Makita LC1230 Cold Saw

Makita’s LC1230 cold saw is our runner-up. With a 12-inch depth, it’s not quite as flexible as the DeWalt DW872 but just as fast. On a lark, we had it cut through ¼-inch box tubing while someone else used a miter saw to cut through a 2×4; the miter saw won, but it was much closer than we expected.

In addition to being fast, the LC1230 makes cuts so clean you’ll rarely find yourself having to grind them down afterward. The blade never wanders, and the fence makes adjusting the blade angle for bevel cuts easy.

The Makita LC1230 rocks a 15-amp, 120-volt motor capable of 1,700 RPM, and its high-quality carbide blade has a maximum depth of 4½ inches. Some other features we love include the quick-release vise and safety-focused D-shaped handle.

Aside from the smaller cutting depth, the other thing keeping Makita in the #2 spot is the mess it makes on the workshop floor. Its dust collector is only partially effective, so expect burrs to get everywhere while you work.

- Fast, clean cuts

- Good factory-installed blade

- No grinding needed on cut metal

- Blade is calibrated well

- Extra safety features

- Leaves a lot of burrs

- Slightly smaller cutting depth

- Uneven quality control

3. Baileigh Manual Circular Cold Saw – Best Value

We understand that the price is a significant concern for many hobbyists and professionals, so we wanted to spotlight the Baileigh CS-315EU, the best cold saw for the money we’ve reviewed this year.

If you’ve never heard of a “manual” cold or chop saw before, don’t fret; it doesn’t mean you have to provide the power on your own. “Manual” means you manually control the speed of the chop saw by depressing or releasing a lever instead of squeezing a trigger. This is a little more physically awkward but gives you much more control over how the saw works.

On top of that fine-tuned control and its amazingly affordable price, the Baileigh CS-315EU hits all the other high notes we look for in a cold saw, making fast, clean cuts that are cool to the touch.

A few things are keeping us from giving the fullest possible recommendation. The coolant tank is in an awkward position on the back of the saw, making it a hassle to refill. Also, the factory blade isn’t made to the highest standards. You might want to replace it, making this saw less budget-friendly.

- Manual lever gives you fine control over speed

- Cuts are fast and precise

- Stays cool

- Refilling coolant is difficult

- Low-quality factory blade

- Lesser-known company

4. Grizzly Industrial 10″ Cold Saw – Premium Choice

Now we come to our premium-priced option. Usually, with chop saws and cold saws, there’s a correlation between the price and quality since a higher price means better-quality parts were used in the saw’s construction.

With the Grizzly T28366 cold saw, that’s undoubtedly true. This saw’s body is heavy and stable, and it cuts straight and true without rattling. A 10-inch blade makes it only suitable for smaller jobs, but it’s still more than able to handle 90% of the workpieces a hobbyist will run into. Its 1 HP, 115V, 3,360 RPM motor also produces an astonishing blade speed.

It’s low on the list for two reasons. One is the price, which goes far beyond “premium.” It’s nearly three times the average of our other picks. For that much, you should be getting a saw that can chew through any metal and last a lifetime.

Second, there’s a glaring flaw in the coolant system. The hose that delivers oil to the saw isn’t properly attached to the pump. Slight jolts are liable to dislodge it completely, interrupting your job and wasting a lot of good oil.

- Excellent cuts

- Well-constructed

- Powerful motor

- Overpriced

- Coolant hose isn’t attached properly

5. Evolution EVOSAW380 Cold Saw

Evolution tools are hit-or-miss in our workshop. This one hits more than it misses, provided that you’re willing to put in the work to make it stable and secure. If you try to use the EVOSAW380 without clamping and supporting everything correctly, you’ll have a much worse time.

Let’s start with the cutting power. The EVOSAW380’s 15-amp motor and 14-inch blade depth make it a breeze to chew through rebar and 2×2 tubing. It’s capable of cutting ferrous and non-ferrous materials. In our tests, it did well with iron, steel, and copper of varying thicknesses.

Our issues begin and end with the construction. Evolution cut many corners in their quest to make this saw more affordable. Their shortcuts result in the table and vise not being perfectly square with the blade, the miter gauge being off by up to 5 degrees, and the table shaking during cuts.

That’s why we prefer to call the EVOSAW380 an expert saw. If you’re comfortable altering bolts, applying your clamps, and using a shim, you can straighten the blade and enjoy precise cuts for less money. If not, go higher up the list.

- Fast cuts

- Handles all materials easily

- Burr-free

- Cheap

- Saw blade isn’t square

- Aluminum base

- Miter gauge is imprecise

6. Evolution RAGE2 Cold Saw

This is an impressive saw, especially considering the low cost. It goes through angle iron, square tubing, and similar stock. It cuts oak wood full of nails, then turns around and cuts steel fence posts with no problem.

Setting up to make miter cuts is easy, and the saw holds the angles quite nicely. It leaves a clean, cold cut and has good durability on the blade teeth. The blade that ships with it, however, is a general-purpose one. You’ll have to get other blades for specific materials.

On the downside, this saw is very loud before it starts cutting. The base and clamp are stamped steel instead of cast. Consequently, there is flex that shouldn’t be there. You’ll need to reinforce it when cutting at an angle. Additionally, the clamp doesn’t have a quick release for making fast adjustments. You’ll have to use an Allen wrench to get the job done.

This is a good, low-cost saw with just enough problems to keep it out of the top 5.

- Good power

- Makes clean, cold cuts

- Good miter cuts

- Too loud

- Base and clamp are stamped steel

- No quick release on the clamp

Buyer’s Guide – Choosing the Best Cold Cut Saw

Here at Home Grail, we get how frightening it can be to drop $400 on a power tool without being sure it will do the job. While no battle plan is entirely safe from the enemy, we put together this buyer’s guide to help you cut the uncertainty down as far as possible.

What Makes a Good Cold Saw?

It’s right there in the name; cuts produced by a cold saw are immediately cool to the touch. Abrasive saws generate tremendous amounts of heat, which leaves metal hot enough to give you third-degree burns. That kind of heat can also deform the metal.

If a cold saw generates sparks and heat, there’s not much “cold” about it. A few sparks here and there are expected whenever you have metal-on-metal, but a continuous shower of them indicates a bad saw. A good saw should also be stable, free of vibrations, and sturdy.

Smooth, fast cuts are a necessity in a good saw. If you’re in the market for a cold saw, you’ll probably be cutting more than just a few pipes. A slow saw can stretch a few hours of work into an all-day marathon, whereas a fast one can keep you moving right along.

How to Choose the Right Saw for Your Needs

Step 1: Define Your Project

Your first order of business with any tool purchase is to figure out what you plan to use it for. There’s a world of difference between cutting a bit of pipe to accent a woodworking project and cutting yards of 2×2 ¼-inch tubing to weld into a two-story frame.

Before shopping for a cold saw, answer these questions:

- Where is your worksite? Most cold saws aren’t portable. You can lug these to job sites, but it’s not easy. They’re best for tasks you can do in your workshop.

- What metals are you cutting? The critical distinction here is ferrous (contains iron) vs. non-ferrous (doesn’t contain iron). Ferrous materials are a lot harder than non-ferrous, so to cut them, look for more powerful motors and a diamond or carbide blade.

- What size are the materials you’re cutting? This determines the blade depth you need. Bigger workpieces require a larger blade. 10 to 14 inches is the average range.

- Do you need to cut at an angle? Many cold saws can miter or bevel up to 45 degrees in either direction; some can miter as high as 90.

Step 2: Rule Out Abrasive Chop Saws

While nothing is entirely objective in woodworking or metalwork, it’s not very controversial to say that cold saws are superior to abrasive saws in almost every way. Abrasive saws are loud and wear out quickly. They fling dust and sparks everywhere. In fact, they only have two advantages: they’re cheap, and they’re fast.

If you’re looking for a saw to quickly chop a lot of metal, an abrasive saw might look appealing. However, since abrasive chop saws leave metal edges uneven, you might waste a lot of the time you save. When facing time constraints, abrasive saws are a good option. In all other situations, pick a cold saw.

Step 3: Check Out The Parts

We advise a part-by-part approach to comparing cold saws. In this section, we’ll list the components you should evaluate.

- As we said above, this will vary based on the type and thickness of metal you’re cutting. As a rule, the harder the workpiece, the more teeth you want. If you like everything about a particular cold saw except the blade, you can replace it, but nothing’s better than when the pre-installed blade works.

- The motor drives the blade. More power equals more RPM, which results in a faster cut with less bouncing. Use 15 amps as a soft minimum for engine power.

- Bevel/miter angle. If you need to cut at an angle, buy a saw that can do it.

- Coolant system. This is a common point of failure on cold saws. Make sure whatever you’re buying has a tank, pump, and hose that won’t come apart under stress.

- Cast iron is the gold standard. Be suspicious of anything softer. Why would you use a base that your saw can cut through?

- Chip collector. A perfect cold saw wouldn’t leave any debris, but no tool is perfect. Look for a cold saw with a tray where burrs and other solid debris can gather for easy cleanup.

Step Four: Buy Extras

Besides the saw, you’ll need a few things to make your purchase complete.

- Safety gear. At the bare minimum, wear gloves and eye protection at all times. We strongly recommend earmuffs and a dust mask too.

- Extra blades. You might never need one, but disasters happen. You also might want multiple blades with different tooth counts. For each type of blade you own, have at least one backup.

- Some cold saws, like the EVOSAW 380, do not require coolant but must still be lubricated. Apply oil regularly to the hinges and gearbox.

- Cleaning brush and pan. This can help clean up any burrs that escape from the chip collector. We don’t advise blowing on metal chips to clear them away; that just increases the risk that they’ll fly into someone’s eye.

- Portable clamps. You won’t always find that the vise on your cold saw’s stand works the way you like. It’s good to have a few of your own clamps on hand to be sure the workpiece stays stable.

- The worst thing a cold saw can do (outside of serious injury) is start wandering, forcing you to make imprecise cuts. A carpenter’s square is a quick way to check that the blade is steady at 90 degrees.

Step Five: See If There’s A Warranty

Step Six: Decide How To Buy

You have two choices; go to your local hardware store, or order online. Each has its pros and cons. You can handle and inspect the saw at the hardware store and maybe even test it out. You can also carry it out right after you buy it. But you’re stuck with whatever deal they offer you, and you’re on your own for getting the saw home.

Online, you can’t see the saw. You have to trust the words of other people who have bought it. However, you’re far more likely to find a reasonable price, even with shipping costs added. Plus, you can have it delivered directly to your workshop. All you’ll have to do is get it inside.

Conclusion

We put each of these cold saws through a trial by fire to write these reviews, but the DeWalt DW872 came out on top. If you like the idea of getting clean cuts for years on end without having to replace the blade constantly, this is the tool for you.

Our best-value cold saw pick for your money is the Baileigh CS-315EU. If you can get used to a European-style overhead lever, you can enjoy fantastically cool and clean cuts for exceptional savings. If you’ve never bought a cold saw, we hope our reviews have inspired you to ditch abrasive chop saws for good and come over to the cool side.

We genuinely hope our overview helps you find the best cold saw for your needs. Thank you for reading, and we’ll see you at the workshop!

Contents