20 Different Types of Drill Bits & Their Uses – Which is Right for You?

-

- Last updated:

The following is a comprehensive list of the most common drill bits and their uses. Read on to find the most appropriate drill bit for your project.

Materials & Coatings of Drill Bits

There are numerous types of drill bits. To help you understand them better, we shall first discuss the construction of different bits:

Material

Drill bits are made from different materials to suit their purpose. Using the right bit material enhances your efficiency. It also prevents you from losing money and purchasing a drill bit that cannot handle your project.

While almost all bits are made from metal due to its toughness, the difference comes in the metal composition. The following are some common materials used in drill bits.

High-Speed Steel

High-speed steel (HSS) is one of the most commonly utilized materials in manufacturing drill bits. It is suitable for drilling wood, plastic, and soft metals. High-speed steel bits are made from carbon steel with chromium and vanadium additives.

Cobalt

Thanks to cobalt’s immense structural strength, cobalt drill bits are especially adept at drilling through stainless steel and other tough materials. Cobalt alloys have an exceptional ability to withstand heat and resistance. Sometimes, these drill bits consist of an alloy of cobalt and HSS. Such an alloy guarantees a bit that can go through almost any surface.

Carbide-Tipped

Carbides are one of the strongest substances on the planet. In fact, some carbides rival diamonds for the hardest material known to man. They are formed when carbon is combined with metal. Nonetheless, carbide is extremely expensive. As a result, making an entire bit out of the substance would not be feasible. This is why manufacturers prefer making only the tips out of carbide. Carbide-tipped bits are typically used for masonry, tile, and concrete drilling.

Solid Carbide

When handling projects involving extremely tough materials, it would be a good idea to consider solid carbide bits. Unlike carbide-tipped bits, solid carbide bits consist entirely of carbide.

Coating

You can also classify drill bits according to the coating they have. They include:

- Black Oxide: Helps the bit to retain lubricants to prevent the onset of rust.

- TiN Coated: TiN refers to titanium nitrate, which slows the progression of wear on bits that drill hard metals

- TiAIN Coated: Titanium aluminum nitrate coating increases a bit’s resistance to abrasion and heat

- SG Coated: A silicone multilayer that helps a drill bit to penetrate dense metals.

The 20 Types of Drill Bits

1. Twist Drill Bits

Also known as high-speed bits, they resemble corkscrews and are some of the most popular bits. They are typically used to drill small holes into wood and walls. Their unique design allows them to channel dust from the hole as they work.

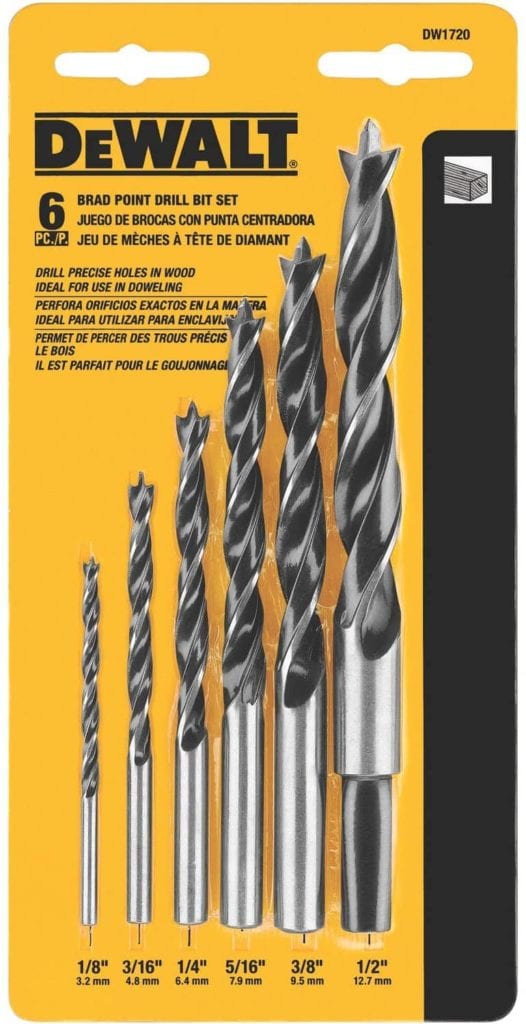

2. Brad Point Drill Bits

Brad point bits come in handy when making clean and precise holes. They come with rubber stoppers to allow you to set a particular depth. Their precision makes them a popular bit among woodworkers.

3. Masonry Drill Bits

These are what you use when looking to create holes in bricks, stones, or concrete. Due to the tough nature of those materials, masonry bits wear out quickly, meaning that you will need to replace them frequently.

4. Rivet Drill Bits

Rivet bits feature a special design that allows them to drill rivets into thin metal sheets.

5. Spade Drill Bits

Spade bits have a spade-shaped tip that allows them to bore into softwoods. They are typically used to create holes for running cables.

See also: 10 Best Impact Driver Bit Sets – Reviews & Top Picks

6. Installer Bits

Professionals use installer bits to bore holes for installing wiring for entertainment or security systems. The tip of the bit has a tiny hole where you insert the wire you are looking to pass through the material. Installer bits are incredibly long, reaching lengths up to 18 inches to facilitate their work.

7. Step Bits

Named after their tip that resembles a series of pyramid-shaped steps, these bits are what professionals use to drill into sheet metal. Their stepped design allows you to create holes with varying diameters. Step bits are renowned for their versatility.

8. Auger Bits

These are the hole drill bits to use when drilling into thick and dry wood. Thanks to their innovative design, you do not have to apply much pressure when drilling into tough materials. Auger bits have a screw tip that creates the initial hole for the rest of the bit to fall. As a result, holes by auger bits are incredibly clean and precise.

9. Self-Feed Bits

Like auger bits, self-feed bits also feature a screw tip for positioning the bit. They create clean, precise holes, as well. However, since they do not channel the dust away from the hole as they work, you must halt the operation periodically to clear the dust away.

10. Forstner Bits

These types of drill bits are what you use when looking to bore smooth and clean holes into wood. This bit also comes with a pointed tip to allow for easy positioning of the bit.

11. Hole Saw

Hole saws are drill bits that allow you to make large holes, such as those for door hardware installations.

- Related Read: Our reviews of the best pocket hole jigs this year

12. Countersink Bits

These versatile hole drill bits allow you to drill counterbore, countersink, and pilot holes into wood.

13. Plug Cutter

Plug cutters are helpful in professional projects, as they drill holes into the wood while cutting the wood plugs you require to hide recessed fasteners.

14. Tile Bits

These bits come with carbide tips to allow you to bore holes into tiles without creating chips or cracks in the tile. Different tile bits are designed for different types of tiles. Therefore, ensure you check its package to confirm that it can drill into your tiles.

- Related Read: Which tool works best for sharpening drill bits?

15. Adjustable Wood Bit

As their name implies, these types of drill bits can be adjusted to create holes of varying sizes, thus eliminating the need for purchasing bits of different sizes.

16. Annular Cutter

These types of drill bits have a special design that allows them to drill a hole into a material with the purpose of extracting its core.

17. Bits for Metal

Metal bits are built for heavy-duty work, such as cutting steel. They are one of the costlier bits out there.

18. Glass and Tile Bit

These special bits can be drilled through plastic, tiles, glass, marble, and brick. They can also withstand high temperatures.

19. Hammer Bit

You use a hammer bit to create precise holes in concrete slabs when determining the amount of humidity in a concrete slab.

20. Bullet Point Bits

The last type of drill bit on our list is the bullet point bit. These are special bits that can drill through wood, plastic, and metal. They create remarkably clean holes.

Conclusion

Drill bits come in all shapes and sizes. The ideal drill bit is the one that suits your needs best. Consider buying a drill bit kit, as it comes with different types of drill bits to ensure that what you need will always be close by.

You might also be interested in:

- How to Drill a Hole in Ceramic (Step-by-Step DIY Guide)

- How to Drill into Concrete (Step-by-Step DIY Guide)

- How to Drill Through Metal (Step-by-Step DIY Guide)

Featured Image Credit: Pixabay

Contents