How Does a Lawn Mower Engine Work? Parts, Types & FAQ

-

Pete Ortiz

- Last updated:

During the last days of the industrial revolution in the 1830s, Edwin Budding, a British engineer, invented the lawn mower. It was a right-on-time invention as people were getting tired of controlling grass in sports grounds, cemeteries, and public parks.

Modern mowers run on engines and motors. Let us find out how they work.

Important Parts of a Lawn Mower Engine

- Carburetor: A carburetor is a small device that mixes air and fuel in a specific ratio for internal combustion engines. Components include a choke, idling, jets, and an accelerator pump. Carburetors are essential in old mowers, cars, power generators, and motorcycle engines, but manufacturers are phasing them out. Taking their place are efficient and low-fuel injector pumps.

- Spark Plug: A spark plug releases powerful sparks that ignite the fuel-air mixture in the combustion chamber by drawing electrical current from an ignition coil.

- Ignition Coil: An ignition coil multiplies the battery’s voltage from 12 or 24V to over 1000V to release a powerful spark in the spark plug. Mowers need a working ignition coil at all times for the spark plug to function.

- Piston: This is a section of the reciprocating engine with a disc that slides up and down inside a cylinder. In short, it is where chemical energy in the fuel is transformed into mechanical energy. Above the piston, intake and combustion valves open and close.

- Intake and Exhaust Valves: An intake valve brings the air-fuel mixture to the combustion chamber, while an exhaust valve takes out combusted gasses.

- Gearbox: A gearbox houses shafts to transmit or convert torque and speed. In the mower, it is a small hand-sized metallic box with two shafts at opposite ends.

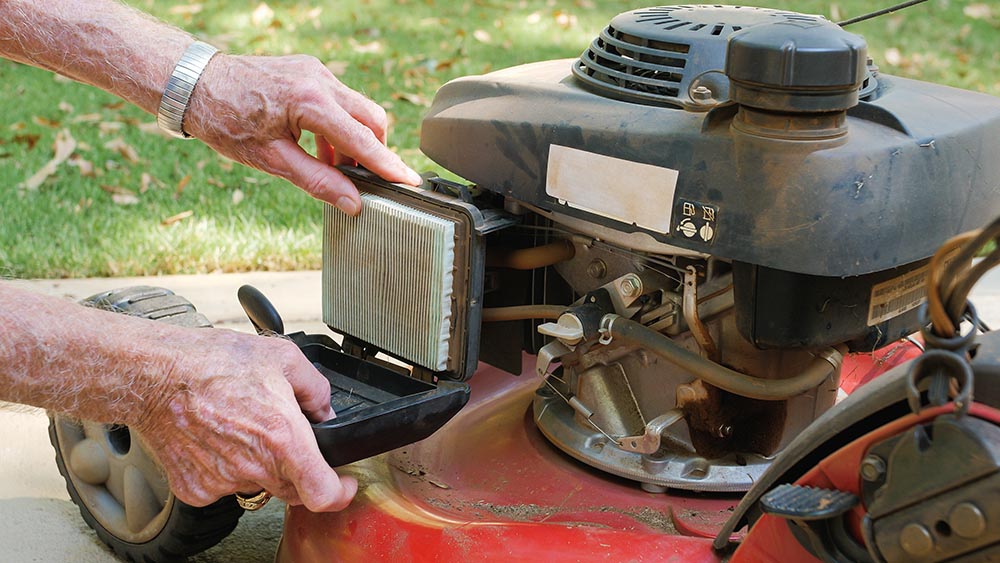

- Air Filters: Fossil fuel mowers have air filters to remove impurities from the air before mixing with fuel in the carburetor. Though a machine can work without one, filters increase its lifespan by preventing impurities from building up in the piston.

- Fuel and Oil Filters: They screen out debris from fuel and oil, respectively. This benefits the piston as it needs clean fuel and oil to run smoothly.

- Safety Switch: A safety switch or operator presence control device stops a rotary mower’s blade from spinning out of control in case of an accident. In addition, it stops the ignition switch from sending power to the spark plug.

Types of Mowers & How Their Engines Work

The market has many top-selling mowers with different working mechanisms. Let us find out how their engines work.

Reel Mowers

A reel mower is appealing to the environment and is pocket friendly. It is small, doesn’t compact soil, is eco-friendly, and requires less maintenance. It is also good for exercise fanatics and can operate in small narrow spaces. Traditional reel mowers lack an engine; instead, they count on a rotating cylinder, a pair of wheels, a handle, and several helical blades to run.

As you exert force on the handle, it rotates a pair of wheels and an axial in turn rotating gears. The first gear is several times larger than a smaller pinion gear. From basic physics, as the larger gear rotates, it transmits power to the pinion gear, which rotates several times faster. This rotational force is known as torque.

Because a reel with blades connects to the pinion gear, the blades rotate the fastest. In fact, if the wheels form a complete rotation, the blades will have completed over five rotations creating the speed and force required to shear through the grass.

In front of the mower, a brush bar folds down tall grass into a spinning cylinder. As accomplished as blades may look, blades do not cut grass on their own. The folded grass will be forced between a cutter bar and blades, where tops will be clipped off, falling on a tray.

Rotary Mowers

Rotary mowers can be broadly classified into electric and gasoline mowers.

Gasoline mowers

A gasoline mower engine has a piston with an intake and exhaust valve and a spark plug. The intake valve brings in a mixture of air and gasoline in a specific ratio from a carburetor. The valve then closes, and the piston compresses the mixture.

A spark plug will then ignite the mixture. Because gasoline fumes are flammable, the mixture bursts into a powerful explosion, becomes hot, and expands. Again, from our high school physics, hot expanding gasses increase pressure pushing the piston outwards. The moving piston rotates a crankshaft, and the entire process begins again. Through gears, speed is multiplied to rotate blades up to 3200 RPM.

Currently, most mowers have four-stroke engines meaning they have four pistons each in a different stage of combustion as the mower works. Four-stroke engines have greater torque, are excellent at converting fuel into energy, and are cleaner compared to traditional two-strokes.

Electric mowers

Electric mowers can be cordless or corded. A corded mower is confined within a 60 to 150 feet radius of the power cord, a limitation that some manufacturers offset by providing longer cords at extra cost. But you will enjoy unlimited working hours provided there are power outlets nearby.

On the other hand, a cordless mower is classy, compact, and silent, but at the mercy of rechargeable lithium-ion batteries.

Most modern mowers have a brushless motor that converts electrical energy into mechanical energy. Inside the motor, there are several coils and a soft ferromagnetic core. As the current flows through the coil, it creates a magnetized zone. The force between the coil and soft ferromagnetic core rotates the shaft, which in turn rotates blades.

To keep the system running, every motor has a commuter. Its job is to keep changing the polarity of a magnet, hence changing the magnetic field that will force the shaft to rotate.

At over 80% efficiency, DC brushless motors are 10% more efficient than standard brushed motors. Additionally, they produce less noise because there is no contact between the rotating shaft and brushes.

Buttons and levers control cutting speed and height.

How Does the Engine of a Hover Mower Work?

When brilliance, creativity, and problem-solving abilities converge together, the final product is a hover mower.

Unlike what pushback and zero-turn mowers present, a hover mower effortlessly floats above from the lifting force generated by fans and blades. Fans connect to either an engine or a motor that rotates it. Here is how they work:

As the blades and fans rotate, the hover mower draws in air from the various points above the deck and lifts it off above the ground like a helicopter. The strategic location of air inlets ensures the air travels directly to the center of the mower. Because this is a high-speed region, the fans push air down at high speed. This creates a high-pressure zone, lifting the mower. As the fans spin, blades attached to the underside rotate, cutting grass and mulching it on one sweep.

Being so unique, hover mowers are very light and lack mowing features like bagging and leaf collection, which may destroy the air cushion between the machine and the ground.

Hover mowers are ideal for slopes where pushback mowers will easily topple over. Furthermore, their small size allows you to push them in tight spaces.

What Happens to a Robotic Mower When the Engine Is Running?

Have an acre of lush grass? No problem, a robotic mower will easily manage over 5000 square feet. At the heart of it is an engine or motor, together with some very sophisticated sensors and software. The motor will draw power from batteries and run the blades. How and when the mower starts, runs, and stops is all run by the sensors and software.

Sensors work with the navigation, charging, and cutting system. The navigation system points the mower in the right direction using boundary wires and radio signals.

A boundary wire is a special conductor that marks the region where you want the mower to work. It forms a closed loop that begins and ends at the charging station and emits an electric signal. The mower uses the signal to change direction and avoid crossing over.

You can install the mower and the boundary wires by yourself or with the help of a technician. Experts will use a special device to lay the wire a few inches below the surface and around flower beds to protect them.

Collision sensors or special sensitive bumpers prevent the mower from hitting walls and trees. So, there is no need to lay boundary wires around them. Besides using boundary wires, mowers use guide wires to pass through narrow corridors. Guide wires also emit signals that will tell the mower to follow it.

Soft obstacles like fallen fruits and shallow holes present no problem. The mower will simply ride over them or change direction. For unmanageable obstacles, an alarm will be tripped off to attract your attention. This is in case the mower falls into a ditch or bogs down.

How Do You Maintain an Engine?

Good and consistent maintenance practices will keep your engine in the best running condition.

- Ensure the lubricating system is working very well: Poor lubrication results in friction between moving parts such as the piston and cylinder. You may notice this when the engine overheats. Ensure your mower engine has enough oil by checking oil levels using a dipstick. Furthermore, read through the manual to determine when is the appropriate time to replace used oil.

- Clean filters frequently: Dirty filters are disastrous to the piston. Clean them frequently with compressed air to remove clogged dust particles.

- Replace broken rings and valves: Piston rings are essential for maintaining maximum compression pressure. They often wear out after some time, and you will detect this when the compression power reduces. Replace them with the help of a mechanic.

- Replace old spark plugs: When spark plugs are not working properly, the engine misfires. It is a common problem in cars, but it may affect a mower too. Replacing a spark plug will cost you around $10. But you can do it on your own.

- Patch up leaks: Loose seals and accidents may result in oil or fuel leaks. Patch up leaks to prevent loss of fuel and oil. Fuel leaks are easy to detect as the engine will be running for a limited time following a refill. You can detect oil leaks by looking at the floor for oil patches.

In Conclusion

Mowers have different operation mechanisms and engines. For example, reels use scissor-like blades rotated by manual force, while rotary mowers have an engine or a motor. An engine has pistons, spark plugs, and valves. The intake valve will bring in an air-fuel mixture to be ignited by a spark plug. The exhaust valve will complete the process of releasing exhaust gases.

Electric mowers can be cordless or corded with brushless or brushed motors. Brushed motors are prominent because they last longer and are more powerful.

Living in a high-octane technological era, robotic and remote-controlled mowers are reshaping the industry. However, despite hosting sophisticated software and sensors, they still require a humble engine to run.

- https://whirltronics.com/lawn-mowers-a-brief-history-and-surprising-facts/

- https://home.howstuffworks.com/reel-mower.htm

- https://www.eia.gov/energyexplained/gasoline/history-of-gasoline.php

- http://www.autolife.umd.umich.edu/Environment/E_Overview/E_Overview3.htm

- https://www.briggsandstratton.com/na/en_us/support/maintenance-how-to/browse/history-of-the-lawn-mower.html

- https://www.quora.com/How-fast-do-the-blades-of-a-lawn-mower-rotate

- https://electronics.howstuffworks.com/motor.htm

- https://www.kbb.com/spark-plug-replacement/

Featured Image Credit: Sergey and Marina Pyataev, Shutterstock

Contents