How Does a Pulley Work? The Surprising Answer!

-

Pete Ortiz

- Last updated:

Lifting heavy objects can be such a hustle. Fortunately, a pulley can make the work easier. A pulley is one of the non-motorized simple machines and is essentially a collection of one or more wheels where one loops a rope to make lifting heavy objects easier.

You can even increase the pulley’s effectiveness by adding more pulleys to the setup. Therefore, if you need to lift heavy objects, do not break your back doing it. Instead, use the power of physics by utilizing this useful device. Read on to learn more about how it works.

How Do Pulley Systems Work?

Pulleys may be considered simple machines,1 but they help us multiply forces. These machines use a grooved wheel, which pivots on the axle. When the contraption is installed on a solid anchor, and a rope threaded through grooves on the wheel, it makes it much easier to lift heavy items, even more efficiently than using brute force.

A pulley makes lifting heavy weights easier by amplifying and redirecting the force. It helps by reversing the direction of an individual lifting force. As one pulls down the rope, the pulley lifts the weight. When two ropes and wheels are used on a pulley, the effort required to lift the load will reduce by half.

The more wheels on a pulley system, the more rope you can use to loop around them. This is the force required to lift a load of similar weight. Below is how different pulley systems work:2

One Wheel

When you wind a rope on a single wheel, the pulley will reverse the direction of the force you will use to lift the weight. Therefore, to lift the weight, you must pull the rope down.

For instance, if you are lifting items weighing at least 100 kg, you must pull the rope with a force that is equivalent to 100 kg (1,000 newtons).

So, if you are lifting your weight 1 meter off a surface, you must pull the loose end of the rope for a meter on the other end.

Two Wheels

If you add more wheels and loop a rope on the grooves of the wheel, you will significantly reduce the effort required to lift the weight. For instance, if you add two more wheels to the pulley system, the 100 kg item (1,000 N) will now be supported by two parts of the same rope instead of just one.

This means that you can lift the 100 kg mass with just 500 newtons, which is half as much. This is perhaps why scientists claim that a pulley system with two wheels and a rope wound around them produces a mechanical advantage (ME of two.)

Mechanical advantage is simply the measurement of exactly how much a simple machine can multiply force. The more the mechanical advantage, the less force is required to lift an object. However, the distance required to use the force will be greater. The object may rise one meter in the air, but you must pull the loose rope end for two meters, which is twice as far.

Wondering why? Well, to lift a weight of one meter, you must ensure the two sections of the rope rise 1m each. Therefore, you must pull the rope for two meters. You can also determine the mechanical advantage by dividing the distance you pull the rope by the distance the weight has to move.

Four Wheels

You can also use four wheels with a long rope looping around them. The 100 kg mass will now be supported by four sections of the rope (the left-sided ones) while ignoring the loose end of the rope you are working with.

This simply means that each section of the rope will support a quarter of the total 100 kg mass (1,000 newtons). So, to haul the weight into the air, you must pull with 250 newtons.

For the weight to rise one meter, the sections of the rope should be shortened by one meter. So, you will pull the rope end for at least four meters.

A pulley system with a rope and four wheels can produce a mechanical advantage of four. This is twice as good as a pulley with a rope and two wheels.

What Are the Different Types of Pulleys?

Pulley systems can have grooves between the flanges, which surround their circumference to support the cable or belt. The driving element of this system can be a rope, cable, chain, or belt.

Below are the main types of pulleys used to lift heavy objects.

1. Fixed Pulley

A fixed system is made up of a wheel attached to a surface such as a floor or a wall and a rope suspended in the air. This allows the pulley to remain stationary while lifting a heavy item. This type of pulley system reduces the amount of force required to lift a load.

Furthermore, a fixed pulley allows an individual to redirect the force required for the task. Therefore, instead of directly lifting the load with upward force, you get to lift the heavy item by pulling the rope downwards.

This type of pulley system is used in curtain blinders, flag poles, and even wells. Fixed pulleys can be made from plastic, wood, or even metal, but this will depend on the type of application.

2. Moving Pulley

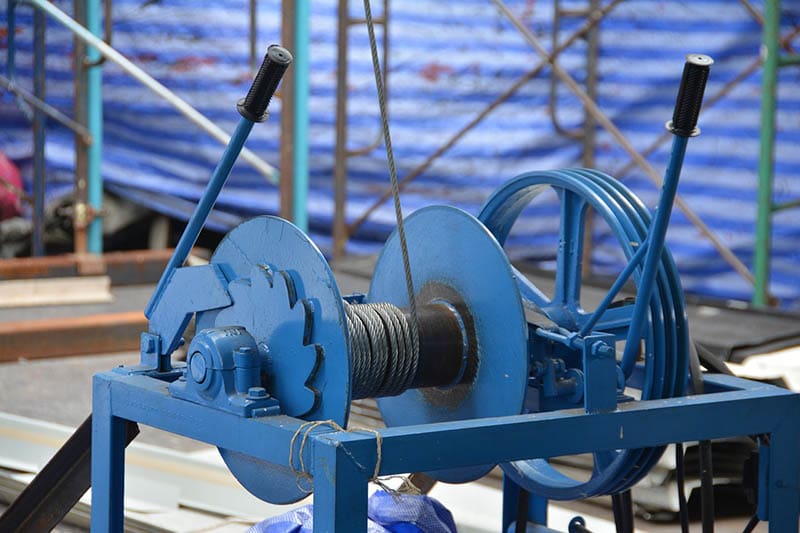

Also referred to as a movable pulley, a moving pulley is essentially made up of wheels that are not fixed on a specific surface. Instead, a cable or rope is fixed on a stationary surface such as a wall. This system produces a mechanical advantage that allows the pulley to reduce the amount of force required to lift a heavy load.

With a moving pulley system, the load is attached to the wheels instead of using the ropes. When one pulls the rope, it slides the wheel on the rope, which then pulls the load with it. This significantly reduces the force required for the action instead of lifting the load directly, which takes herculean effort.

Moving pulleys are commonly used in utility lifts, cranes, and even lifting machines.

3. Compound Pulley

This type of pulley system consists of both a fixed pulley and a movable pulley. This pulley combination not only significantly reduces the force needed to lift a load but also allows a person to change the force direction.

Granted, this configuration will allow you to lift heavy objects; however, there is a caveat. You need more speed to lift an object effectively.

4. Other Types of Pulley Systems

Block and Tackle

Block and tackle are essentially a variation of composite pulleys that significantly reduce the force needed to lift a heavy object. This system consists of several movable and fixed pulleys arranged at a parallel angle.

The fixed pulley is aligned directly opposite the other fixed pulley. It is also movable. Each of these pairs is connected to the next one, with each set reducing the total force needed to move an object.

Block and tackle pulleys are used in rock climbing, sailboats, garage, shop shutters, and the curtains used in theaters.

Cone Pulleys

Cone pulleys are made up of several pulley wheels, which reduce in circumference when stacked on top of each other to create a cone shape. The cone shape form it takes allows individuals to redirect the speed of the pulley. The smaller circumference section of the wheels will require less force, but it also generates less force.

Cone pulley systems are used in multi-gear bicycles. With a few flicks of the gear system on the handlebars, a cyclist can shift between smaller gears that help rotate the bike less and higher gears which will need more effort to rotate the bike for more distances per revolution. Cone pulleys are also used in roving and drilling machines.

Conveyor Pulleys

Conveyor pulley systems also change the conveyor belt direction, provide belt tension as well as and drive the belt. This type of pulley consists of rolled shells with locking assemblies and flexible end discs. The rolled shells are located near the motor or on one side of the conveyor.

Guide Pulleys

These are smaller versions of idler pulley systems that help guide the cable into the groove of a pulley wheel and run it along a specific path.

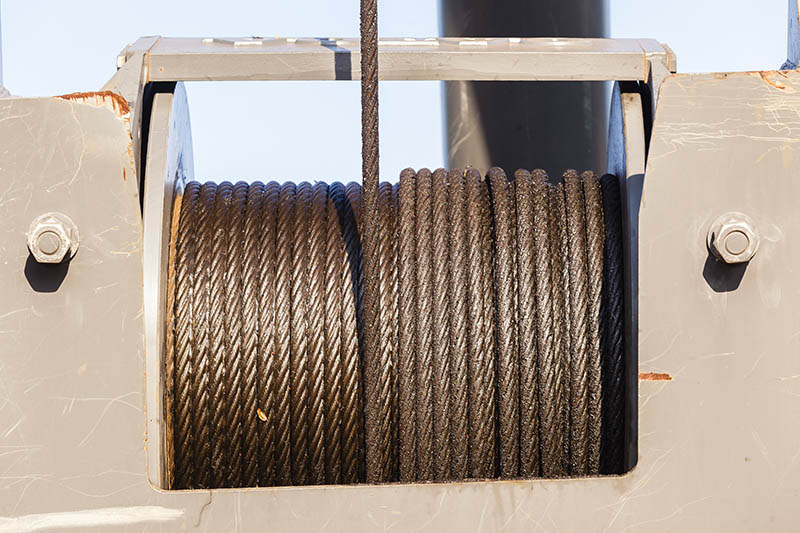

Drum Pulleys

While the common standard pulley systems use a single groove for chains, belts, or cables, drums are a larger type of pulley used in cable systems. They allow the cable to loop around the diameter of the drum several times.

Sprocket Pulleys

A sprocket is what is used to drive chain systems in a pulley. It has teeth-like serrations along the diameter to catch the chain links and propel the pulley forward.

Where Are Pulley Systems Used?

The primary function of a pulley is to lift heavy objects by changing the force direction on a flexible conveyor cable. With the help of chains, ropes, or cords, a pulley system makes lifting objects upwards significantly easier. A functional pulley should be able to reduce the force required to lift a load.

Pulleys are commonly used in different industries to apply force, lift loads, and even transmit power. Pulleys and belts can transmit power in constricted spaces and large areas, an advantage they have over gear.

Since most pulley systems are run by the friction created between the belt and the pulley, if any of the components in the mechanism fail, the belt transmitting the power slips on the pulley wheels instead of making the motor stall.

Pulley systems typically allow workers to save energy and time when lifting heavy objects. This is perhaps why pulley manufacturers are committed to making the work of lifting heavy loads more manageable.

Here are some examples of how pulleys are used in our everyday lives.

- Weight lifting machines: Simple machines that utilize the use of resistance with cables often rely on pulley systems to change the direction of the force used while lifting heavy loads.

- Flag hoisting: Flagpoles are basically equipped with a pulley system at the top to help lift a flag along the rope.

- Window blinders: The closing and opening mechanism on window blinders utilize a pulley system.

- Construction: From fixed pulleys to the cranes found in construction sites, pulley systems are essential tools for lifting heavy construction materials.

- Elevators: In case you might not have noticed before, the up-and-down movement of an elevator utilizes a powerful electronic pulley system.

- Wells: To lower and raise a container into a water well, you need a pulley system.

- Theater curtains: The heavy curtains installed in a theater utilize several pulley systems to open and close them.

Advantages of Pulleys

- When mounted on an engine, a pulley can also be called a belt. A belt can be exposed to different metals or oil and easily transported.

- It offers a mechanical advantage when lifting heavy objects, thus creating a profitability known as the effort-to-load ratio.

- Also known as load pulleys, movable pulleys help reduce the distance range, with long ropes acting as props.

- They are less expensive and easier to use when compared to ordinary lifting gear.

- Pulleys do not require lubrication to be functional.

- You can apply force by pulling the ropes in a pulley system in any direction and rely on the load and effort relationship.

Disadvantages of Pulleys

- When transferring the direction of the force in a pulley system, fiction is created, thus increasing the likelihood of slipping.

- The rope can slip when pulled at the sides, thus forcing the rope to move out of the groove tracks, which can cause injury.

- When compared to gear systems, pulleys are less reliable.

- Some complex pulley systems rely on additional ropes and multiple wheels to support heavy-weight loads, which can be costly.

Frequently Asked Questions (FAQs)

How is the pulley ratio calculated?

You can determine the ratio between any two drive accessories by dividing the diameter of a smaller pulley by that of the larger one. For instance, if a water pump pulley measuring 6 inches long is combined with a crank pulley measuring 7 inches, the ratio of the pulley would be 1.16: 1.

How can you calculate a pulley mechanical advantage?

The most accurate method of determining the mechanical advantage of a pulley with a belt drive is to divide the diameter inside the driven pulley wheel from the diameter inside a drive pulley wheel. Alternatively, you can make a comparison of the number of rotations from a driven pulley wheel to a single rotation of the drive wheel pulley.

Which pulley system increases speed, a smaller or bigger one?

Normally, the bigger a driven pulley is, the more slowly it is likely to turn. However, more torque is produced. On the other hand, the smaller your driven pulley is, the faster it will rotate, but with less torque.

What are the most common types of pulleys?

There are four types of pulleys you can find on a worksite. They include moveable, fixed, complex, and compound pulley systems. However, compound pulley systems are essentially a combination of moveable and fixed pulleys.

Conclusion

Pulleys are essential tools used in the construction industry and other aspects of our lives. These tools can increase the amount of force applied and/or change the direction of the force. The combination of an axle, a wheel, and a rope assists various professions in lifting heavy loads at the workplace.

The most common types are moveable and fixed pulleys, each with a unique purpose. They affect the input force required to lower or lift an object. Usually, the input and output force in a fixed pulley system remains the same.

Yet, a change in the force direction can make lifting heavy loads easier and more comfortable. On a movable pulley system, the force is significantly increased, with each side supporting half the weight of the load.

Featured Image Credit: Nasruddeen Alanthi, Shutterstock

Contents