How to Use a Lathe: 5 Tips & Tricks

-

Pete Ortiz

- Last updated:

Lathes are crucial tools for woodworkers; these are machines that help create an object by spinning a cylindrical mandrel while cutting or shaping various materials. You can use a lathe to shape or cut metal and wood. If you learn to use a lathe, you can create beautiful wooden and metal gifts and furniture easily. A lathe is also an excellent addition to your tool collection. It’ll help make your project better.

If you have never operated a lathe before, you are in for a treat. In this article, we’ll show you how to use a wood and metal lathe step-by-step. We’ll also give you some tips on getting started after that. But first, let’s define a wood and a metal lathe.

Definition of a Wood Lathe and Metal Lathe

Wood lathes are also known as stationary manual or rotary hand tools. They shape the wood into the desired shape. They’re less expensive compared to other types of power tools. You can use wood lathes for various purposes, including turning wood into decorative items and creating woodworking projects.

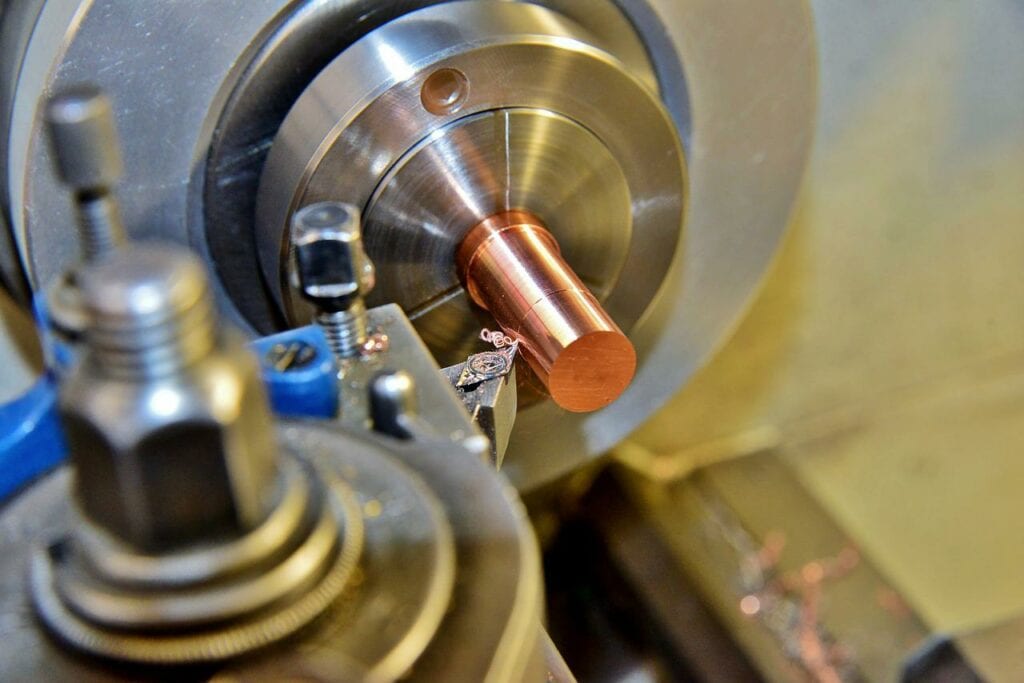

On the other hand, a metal lathe shapes and cuts metal objects. Usually, these machines are used by professional machinists and industrialists. You can use a metal lathe to turn various kinds of metals, including aluminum, brass, copper, stainless steel, and many more.

A metal lathe has a rotating spindle mounted on a carriage. It slides along the machine bed. It can rotate along with the spindle. So, it allows for accurate cuts on different metals.

Step-By-Step Guide for Using a Lathe

Before You Start

Before using a lathe, there are some things you should do as seen below:

- Check the safety of the machine: Make sure the lathe is in excellent working condition and remove any tools from the lathe bed.

- Make sure that all the lathe cutting tools are sharp: Sharpen all cutting tools you will use. You should also wear protective glasses when operating the lathe but don’t wear gloves or a watch as they may get entangled by the lathe machine.

- Read all instructions carefully: Before starting to use your lathe, read the owner’s manual. It has crucial information about how to operate your machine safely and efficiently. It also has information on maintenance and safety procedures you must follow when running your lathe.

So, now you know what to do before using your lathe and how it can help you create many things. Let’s get started using one! Here, we’ll look at how to use wood and a metal lathe.

How to Use a Wood Lathe

- Come up with a project: First, decide what type of project you want to make. You can make a simple bowl or a complex piece of furniture. The choice is yours! The purpose is to turn an uneven wooden piece into a cylindrical shape.

- Choose a suitable lathe for your project: Comparing lathes is a complex process, but it’s not impossible. An excellent way to start is by choosing a lathe that fits your budget, but make sure it suits your needs. Wood lathes come in two categories. There’s a benchtop and an advanced lathe. You can use the advanced lathe for advanced factory and woodworking roles. On the flip side, you can use a benchtop lathe if you have a small project.

- Choose an ideal tool: You need chisels for your lathe work. With these tools, you can shape your project to your satisfaction. Some people prefer to buy their tools. Others prefer renting them from professionals who have experience with these machines.

- Choose suitable wood for the project: Make sure you have a suitable type of wood and that it’s dry and free from dust and dirt. There are many different types of wood, each with its characteristics and uses. Some types of wood are better suited for some projects than others. So, consider this before you buy the wood.

- Select the wood length you want to work with: Start with a length about 1/2 inch longer than the desired finished length of your project. It can be as much as 2 inches longer than the project when working on larger projects. It allows for any measurement errors and more room for error on your part when cutting the wood.

- Mark the center of the wood and position it: Put the wood in a precise position and mark the center. Then, put the wood between the centers of the lathe and fix it firmly into position. Ensure you place the wood piece in the correct position and that the procedure has no flaws.

- Put the tool rest in an adequate position: The tool rest should be parallel to the wood piece. The distance between the tool rest and the wood piece should be small, but it shouldn’t be too close as it may interfere with the lathe’s rotation.

- Pick a suitable chisel: The best chisel is the roughing gauge. It can change any uneven piece of wood into a smooth cylindrical wooden piece. You should also hold the tool well on the tool rest. Make sure you also get better control by leaning your body weight towards the lathe.

- Start the work: Switch on the lathe once you’ve set up everything. Ensure the lathe’s speed is minimal to prevent any error or accident. Bring the tool rest gradually towards the rotating piece of wood. It’s only supposed to come into contact with the wood surface and get shaped together. You may have a few errors as you begin, but don’t worry as it’s only your first trial.

- Repeat the same procedure using the complete length of the wood piece: Once you’re through with the first trial, repeat the entire procedure to the whole piece of wood. Let the cutting edge be parallel to the wood piece. To reduce errors and have better results, make a light cut to the length. When working, twist the tool to the left and right. This way, you’ll not be covered by the chips.

- Push the tool towards the stock of the lathe: Pushing the tool towards the stock repeatedly will help you remove equal parts. It’s also the best method of removing angular parts. This way, you’ll get the cylindrical shape you want.

- Check your work often: Inspecting your work enables you to keep track of your progress. Make sure that it’s still straight and level. Use a square or other ruler to check that the parts are positioned well on the lathe bed. If not, adjust the position until it’s properly aligned.

- Make the wood piece smoother and sand it: Reduce the contact surface between the wood piece and the tool. Then, increase the lathe’s speed. Your tool rest should rarely touch the wood piece if you want the utmost smoothness. Then, use sandpaper or an orbital sander and sand the wood piece. Sand it gently.

How to Use a Metal Lathe

- Set up the lathe and the cutting tool as per your project: Setting up the lathe is the first step. It can be tricky at first if you haven’t done this before. But once you get the hang of it, it becomes second nature. Usually, you can attach a small bench lathe to a steady bench or pedestal.

- Attach the workpiece to the lathe’s headstock: The headstock is where you put your workpiece and then turn it around. It has a handle that you can use to move your workpiece around. Also, ensure you’re wearing a chuck guard. Then, choose the direction you want the lathe to rotate.

- Rotate the lathe: Switch on your machine. Make sure that it’s in the correct position. Then, make sure there are no hands or other objects in the way of the headstock.

- Move the tool post close to the rotating workpiece: You can adjust the tool post after you have set up everything. Also, make sure that your tool post is parallel to the face of your lathe bed.

- Slide the carriage: Sliding the carriage allows you to set the cutting tool correctly. You can use several cutting tools to carry out different operations.

- Turn off the switch: Switch off the machine after carrying out your first light pass. Then, repeat the process. Once you’re through with the light passes, your workpiece will be moving to the shape you want.

The 5 Tips & Tricks on How to Use a Lathe

Now that you know how to use a lathe, here are several tips and tricks to help sharpen your skills.

1. Simple maintenance prolongs your lathe’s life

If you perform regular maintenance, you can keep your lathe running smoothly for years. Make sure you oil and lubricate the parts often. Also, ensure no loose parts or problems will cause damage. The best way to maintain your lathe is by keeping it clean.

2. If you have a good center finder, you’ll reduce extra work

You’ll reduce extra work since you won’t have to make adjustments manually when working on your lathe. A center finder aligns itself automatically with the center of the material you’re turning on your lathe. It also keeps it in place.

3. Upgrade your tool rest

Usually, tool rests are made of cast iron, which can scratch easily. You can combat this by installing a stainless steel tool rest that doesn’t dent or scratch easily.

4. Switch off your lathe before making any adjustments

When you want to adjust the lathe, turn it off first. Otherwise, you’ll end up damaging the machine or hurting yourself.

5. Put on suitable gear

Wear eye protection at all times when using a lathe. Also, keep dust away from your face and eyes as much as possible. Breathing in wood dust can cause problems with breathing or eye irritation.

Conclusion

Lathes are versatile tools. In a short time, you can accomplish many impressive and fascinating projects. So, there you have it. This guide is for you if you want to learn how to use a lathe. Don’t forget your safety. We can’t emphasize enough how crucial it is.

Follow these guidelines as closely as possible. With this, you’ll create beautifully crafted projects of your own. Now, you have mastered a challenging but rewarding skill.

Featured Image Credit: QBR, Shutterstock

Contents