11 Different Types of Lathe Tools (With Pictures)

-

Pete Ortiz

- Last updated:

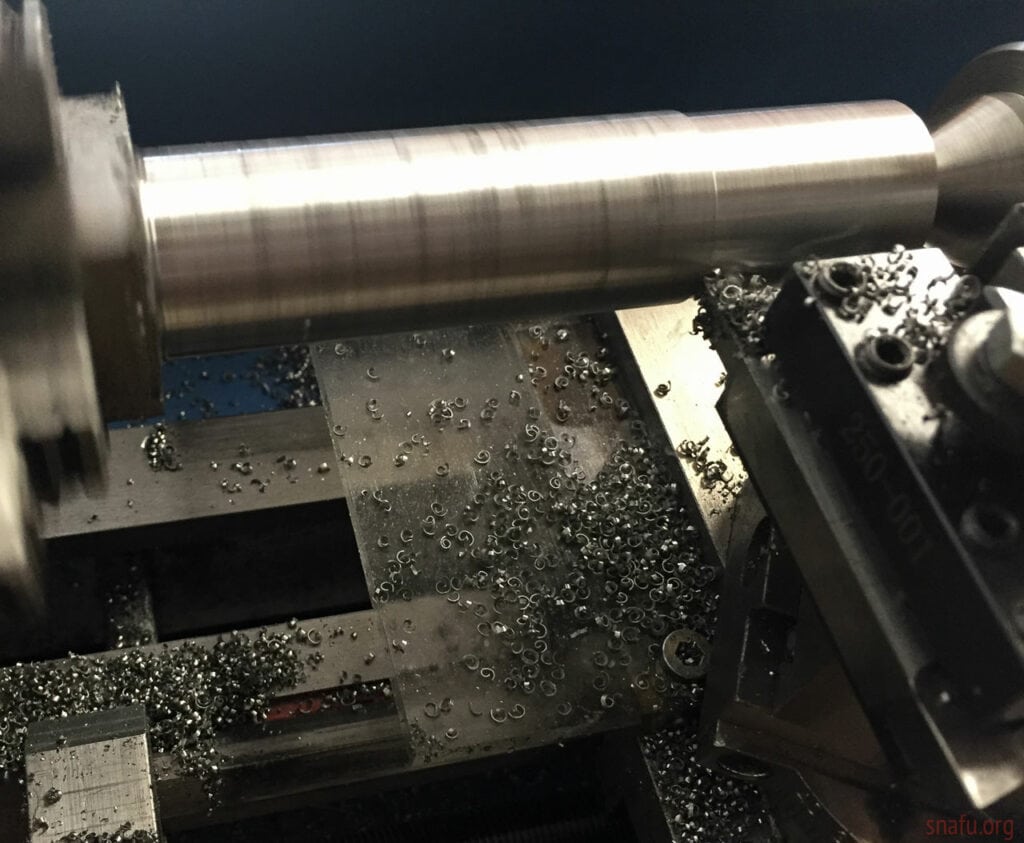

Lathe tools are machining tools used in shaping various materials such as glass, metal, and wood. These tools add the versatility of the lathe machine in woodworking, metalworking, and glasswork projects. The tools feature a rotating drive to turn a workpiece against the different tools on its axis. They work using a simple grip and rotating mechanisms.

Different lathe tools are used for performing various operations. Depending on the use, they can be used for cutting, drilling, rotating, sanding, or deforming materials. Knowing the various tools helps you know the ones that work best for your metal, glass, or glass project.

This article provides you with the different types of lathe tools depending on their use, the material used to make them, and the method of applying feed.

The 11 Different Types of Lathe Tools

1. Facing Lathe Tools

Facing lathe tools are essential if you want to shorten your workpiece stock and make a smaller diameter. They cut the material from the end to allow it to fit at the correct angle of the axis. So, these are tools that can be applied in a wide range of wood, metal, and glasswork projects.

The tools are simple to install on your lathe machine. Whether you are using a turret lathe, bench lathe, or engine lathe, the facing tools work perfectly. They fit perfectly in the machine.

Good facing tools make it easy to perform any precision work. The cutting edge of the facing tool should be set to a similar height as the workpiece center. Made from steel, facing tools can last for many years working at their optimum levels.

2. Boring Lathe Tools

Boring lathe tools are used to make larger holes than the already existing ones1. You can use the tool to make bigger room for larger screws in the piece you are working on or if you need a bigger hole for any other use. The tool easily bores into the present hole and widens the area for you to work on.

For a boring lathe tool to work perfectly, you must have an existing hole on your piece of work. The tool makes your work easier when building a table or any other piece that needs holes to fit together correctly. You may not often use this tool as the other lathe tools, but it is very critical in its application.

When buying boring tools, ensure you get the one with the correct tips to help get a hole with a specific size. Have several boring tool tip sizes for more efficiency.

3. Chamfering Lathe Tools

Chamfering lathe tools2 help when you want to break off an edge on a piece you are working on. The tool is also used to make a chamfer3 on the edge of the stock. They help in designing furrows or bevels on your bolt. If you have a lot of chamfer work, you should get a chamfer tool featuring a side-cutting angle edge.

The tool features heavy-duty drill bits that help it perform the duty more effectively. You can use a chamfer tool to smooth sharp edges on your workpiece. You should invest in a strong set to simplify work and get high-quality results.

With the angled cutting surface, the tool removes sharp edges in parts, making your work aesthetically appealing and stronger. Getting chamfering tools is easy since you can purchase them in a pack with other lathe tools.

4. Knurling Lathe Tools

Knurling lathe tools are used when you want to craft knobs.4 The tools can also be used for several other purposes, but knobs require a knurling tool to be designed correctly. With the tool, you can grip a knob correctly to perform the intended task on it.

It’s essential to have a knurling tool for all the works that require enhanced grip to allow you to finish your task correctly. It’s possible to adjust the tool to match your requirements.

The tool allows you to produce knurled parts, meaning they produce a pattern of crossed, angled, or straight lines on your cylindrical piece. The knurling lathe tool has toothed steel wheels and a holder that helps in pressing the pattern you want into your workpiece surfaces.

These tools are critical if you want to improve the look of your piece by creating attractive patterns and ridges. You can also use it to create parts or features that need gripping such as screw heads, round nuts, and hand tools.

5. Parting Tool Lathe Tools

Parting tools are a critical part of your lathe. Regardless of the job you want to perform with your lathe machine, you will require parting tools at one point. The tools cut off specific sections of your stock or shorten things. This is necessary as you try to make all your things fit well.

They have a blade-like cutting edge that plunges into your piece directly to cut off materials at a certain length. With a good parting tool, you can resize various pieces effectively and make the work easy. Parting tools can help you not only do simple cuts but also help cut beveled edges, cutting grooves, and shoulders.

The tool saves time and allows you to work more accurately.

6. Channeling Lathe Tools

These tools are used to cut channels into stock when you want to create shallow or circular grooves. These tasks are required to complete many projects, thus making these tools essential.

The tools are designed using rugged materials and will work perfectly regardless of the lathe machine you use. Channeling tools do the grooving work. The tool can help you create holes of particular depth around your piece.

7. Woodworking Lathe Chisels

Woodworking lathe chisels are the most critical lathe tools you will use for different purposes. The woodworking chisel set features five different chisels that serve different needs. These chisels are 10 inches long, with the blades measuring 4 inches long.

The tools make woodworking easier since they can also be used for parting and scraping. These chisels are beneficial regardless of what you want to create. For instance, you can use it for a baseball bat, table, or any other piece.

Included in the set, you get a skew chisel used to keep your wood a smooth finish. These chisels are available in different sizes and shapes, so you can choose different ones to be more effective in your woodworking project.

8. Spindle Gouges

Spindle gouges are used to create coves into your wood piece. To get the best results, you should buy the spindle gouges in sets to have options for different jobs.

The gouges are available in various sizes, so you choose the right ones according to your specific needs. You can get shorter or longer ones depending on the project you are working on.

9. Bowl Gouges

Bowl gouges work the same as spindle gouges but differ in certain aspects. They create deeper gouges in your woodwork piece. They are available in different sizes and styles, so you enjoy versatility when buying and using them. The gouges come in sturdy designs, making them last for many years.

10. Scraper Tools

Scraping tools are essential as you approach the end of your woodworking project. They help you finish flat bottoms and the convex parts of your project. Only the tip of the scrapers gets into contact with the wood.

When your tool is in good working condition, it produces shavings from your piece, and you can use it to finish your woodwork more perfectly. You get scrapers with various types of ends, so you need to select one that has an end suited for your particular job.

11. Grinding Wheel

The grinding wheel is another lathe tool used to do fine woodwork. It’s an easy-to-use tool, making it great even if you are a beginner in woodworking. The tool creates fine precision that most of the other tools may not offer.

Lathe Tools Classification by Material

Lathe tools are also classified depending on the material used to make them. Here are some of the types:

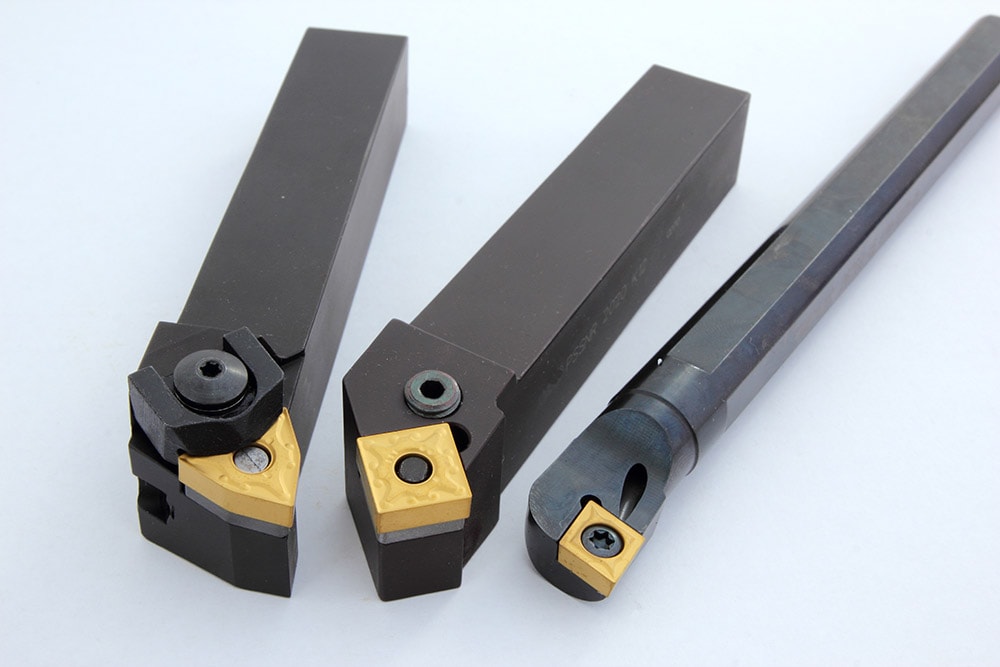

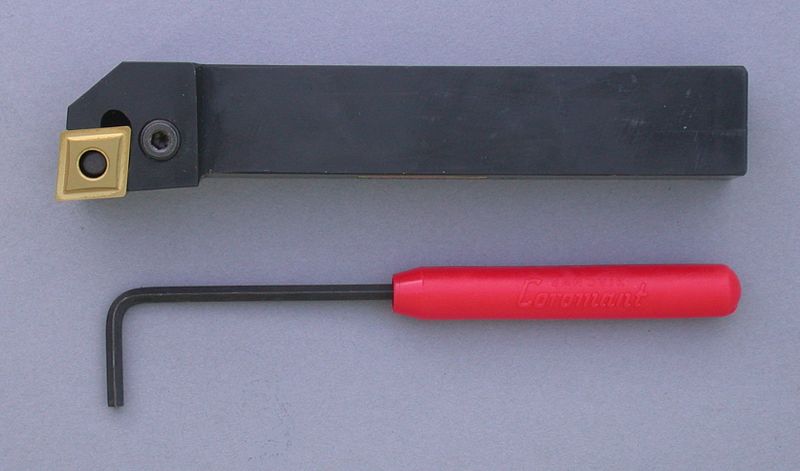

1. Carbide Lathe Tool

These are lathe tools with cutting edges made from carbide. The tools are perfect for cutting plastic, steel, iron, glass, and other hard materials.

2. High-Speed Steel Tool

As the name suggests, these are lathe tools made from high-speed steel that maintain hardness. The tools are suitable for semi-finish and rough machining.

3. Diamond Blade

Diamond is a wear-resistant and hard material. Lathe tools with diamond cutting edge are suitable for precision machining of wear-resistant, brittle, hard, and conforming materials like graphite.

4. Other Materials

There are other lathe tools made from ceramic and cubic nitride. These tools are perfect for cutting hard alloys and rough machining.

Lathe Tools Classification by Method of Use

Lathe tools are also classified depending on the method used to apply the feed as seen below:

1. Right and Left-hand Tool

Right-hand lathe tools usually remove materials from your workpiece from right to left. The tools get the name depending on the human hand analogy. When using your right hand when operating the tool, your thumb represents your tool feed direction. The left-hand lathe cutting tools remove the material moving from left to right.

2. Round Nose Tool

These lathe tools don’t have the side rake or the back rake. Thus, you feed your tool from right to left or left to the right-hand end of the lathe machine. Sometimes, the round nose lathe tool can feature a small back rake. With the round edge, round nose turning lathe tools are mostly used in finish turning operation.

Conclusion

There are different types of lathe tools you can use for your project. They are categorized according to uses, materials, and methods used to apply the feed. You can use the lathe tools for cutting, shearing, parting, boring, grinding, and other deformations.

Most of the lathe tools are available in different sizes, shapes, and other properties. It’s always advisable to buy them in a set so that you can enjoy versatility. The other important thing is to ensure you know how to use the tools and choose the right one for the suitable purpose.

- What Is a Lathe Tool? | Types of Lathe Tools

- 13 Different Types of Lathe Tools

- Different Types of Lathe Cutting Tools for Turning, Boring, Facing, Chamfering and More Operations

- What is Lathe Machine? Main parts, Operations and Working

- Different Types of Lathe Tools You Can Use in CNC Turning

- BOWL GOUGE VS SPINDLE GOUGE DIFFERENCE EXPLAINED

Featured Image Credit: MRo, Shutterstock

Contents