6 DIY Lathe Chuck Ideas You Can Make Today (With Pictures)

-

- Last updated:

A unique satisfaction comes with making your tools, and it’s a sign that you’ve arrived as a home handyman. As a vital component in building so many other tools, there is no better place to start than a homemade lathe chuck. You can take on a broader array of materials with a custom-made chuck, allowing you to expand your woodworking projects into brand new territory.

A lathe chuck is hardly a beginner’s project. Fortunately, if you’re the type of person who needs one, you likely have a shop with all the tools necessary to craft a safe and functional vice. Get inspired for your next DIY design with these seven lathe chuck ideas you can make today!

The 6 DIY Lathe Chuck Ideas

1. Longworth Chuck by Paoson

| Difficulty: | Easy |

If you want to take a measured approach to DIY lathe chuck builds, this easy Longworth chuck is the project for you! A Longworth chuck holds plates and bowls for finishing using several padded nubs that close together.

In this design, eight nubs sit in individual straight tracks, so you must move them one at a time. The adjustments can feel tedious, but you’ll appreciate how fast and effortless the chuck is to build. All you need is a router and a lathe to make your faceplate, and you can complete the project in about an hour.

2. Adjustable Longworth Chuck by So Many Hobbies

| Difficulty: | Intermediate |

Ready to step your Longworth chuck-building skills up a notch? With this adjustable Longworth chuck, a complex design adds loads of convenience. Two autonomously spinning plates hold the grips, and with a single turn, they all expand and contract at once, saving you from painstakingly moving each one to the proper position.

For the chuck to work, the discs need an array of arcs for the grips to follow. Again, you only need a router, a lathe, and precise measurements to finish the project. Once you’ve finished, you will love the smooth functionality and practical efficiency it provides.

3. Jam Chuck by Woodcraft

| Difficulty: | Easy |

Perfect for a variety of plate and bowl-making projects, this jam chuck is a beautiful and uncomplicated addition to your assortment of wood-turning tools. By using pressure and rounded shapes, the chuck allows you to turn materials in a spectrum of diameters without time-consuming adjustments. Its design fits a 4-jaw chuck.

The tool and material needs are slight, and the technique is straightforward. A steady hand becomes essential if you plan to form the chuck to the exact specs. Otherwise, it’s a simple matter of drilling and shaping a piece of wood and adding a piece of neoprene to complete the project from beginning to end.

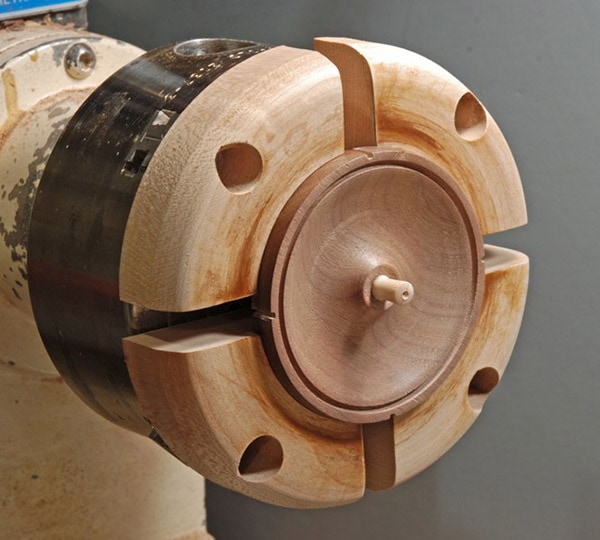

4. Donut Chuck by Instructables

| Difficulty: | Easy |

Since it’s similar to a jam chuck, this donut chuck design lets you turn bowls in several sizes. The difference is that the donut chuck (aka trapped reverse chuck) doesn’t rely on the tailstock to hold the piece, allowing you to work the bottom of a bowl without interference.

The lathe does most of the work to build the donut chuck, which consists of two plywood pieces, a portion of pipe insulation, and four ¼” bolts. The project doesn’t require complex measurements or diagrams, and you can likely build one in only a couple of hours.

5. Collet Chuck by in the wood shop

| Difficulty: | Advanced |

A collet chuck doesn’t have clamps that come together to put pressure on a piece. Instead, it squeezes a workpiece with a collar. With this collet chuck design, you can start turning smaller parts such as cabinet handles.

The tutorial walks you through fashioning a collet chuck from a piece of raw firewood and highlights the financial benefits of making a tool rather than spending a few hundred dollars at the store. The tradeoff is time. Forming the tapered shaft of the chuck and the O-ring takes precision, patience, trial-and-error, and on-the-fly adjustments. It may take several hours to complete, but the pride in the finished product will be well worth the effort.

6. Wood or PVC 4-Jaw Chuck by David Reed Smith

| Difficulty: | Intermediate |

The measurements aren’t demanding, but there’s a lot of building involved in these wood 4-jaw chuck plans. Before you even start making the jaws, the tutorial details how to bring several plywood cuts together to create the jig for drilling the mounting holes. Once completed, you can create several jaw shapes to attach directly onto a metal chuck.

In Summary

A lathe chuck is a project that continues to pay off with every passing job, offering entirely new avenues to follow in your DIY journey. From collet chucks to jam chucks, there are all kinds of unique styles to add to your growing collection of shop accessories. Take the afternoon to dig into one of these DIY lathe chuck ideas, and start broadening your woodworking horizons today!

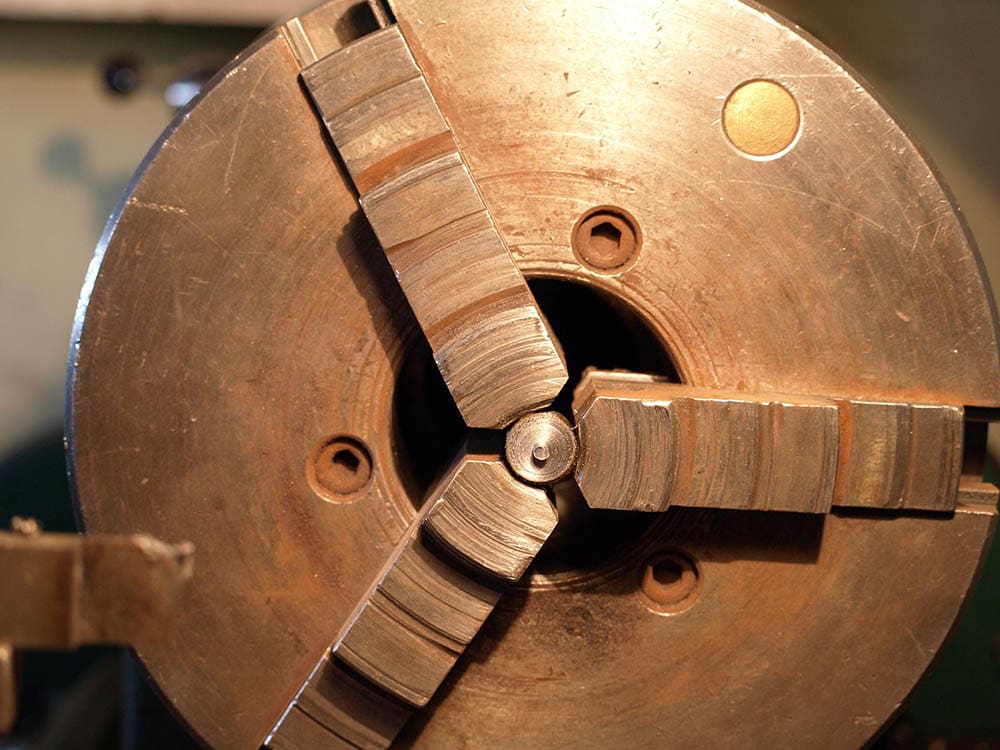

Featured Image Credit: Olarts, Pixabay

Contents