What Is a Lathe? Pros, Cons, Types & FAQ

-

Pete Ortiz

- Last updated:

If you are interested in woodworking or metalwork, one tool you will have to get familiar with is the lathe. This specialty tool is incredibly common within these industries, but most people have no idea what this tool is until they enter the industry themselves.

If you are interested in learning more about a lathe, you’ve come to the right place. This article takes a close look at what a lathe is, how it works, and when it is used. Whether you expect to use a lathe yourself or are just interested in the tool, keep reading.

How Does It Work?

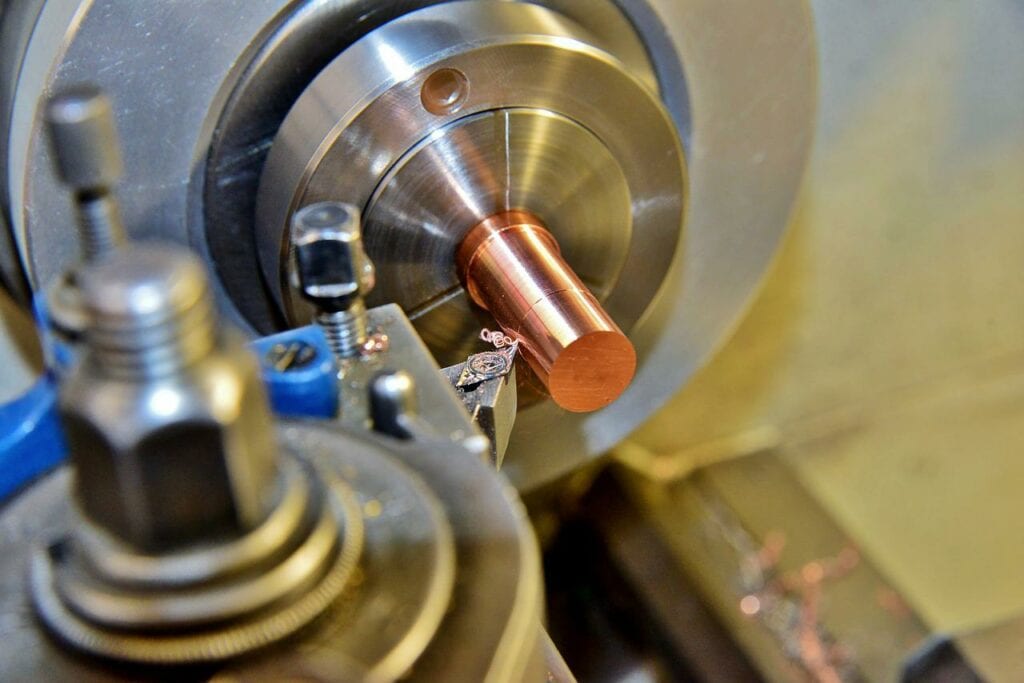

A lathe is a tool that is mainly used for shaping metal or wood. Its main purpose is to remove any unwanted parts of the material, creating a nicely shaped workpiece. This device works by rotating the piece around a cutting tool to shave away the unwanted material.

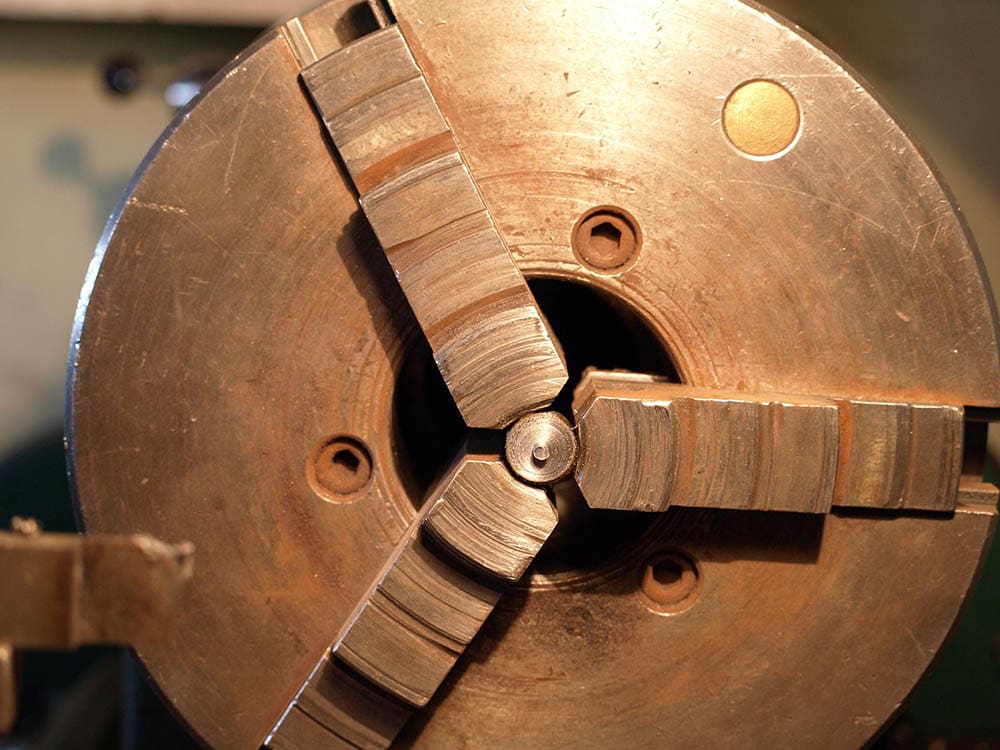

Parts of a Lathe

To fully understand how the lathe works, you have to understand its parts. There are six main parts of the lathe: the bed, headstock, tailstock, spindle, tool rest, and motor.

The bed is responsible for holding all the parts together. Each one of the parts is attached to the bed. The headstock will be on the left of the bed and the tailstock will be on the right.

Most of the action happens on the headstock side. This is where the motor is on most models, though the motor is sometimes placed below the bed. In addition to housing the motor, the headstock holds the spindle in place.

Most lathes will come with adjustable parts. For example, the tool rest allows you to adjust the rotation and height. The tailstock is also adjustable. With the spindles, you can attach different accessories to get the proper finish you want.

It is the spindles and accessories that actually carve away at the material. The motor will power the spindles that your workpiece is on. A cutting tool will be stationary inside the bed and the spindles will move the workpiece against the cutting tool. This motion is what removes the excess from your piece.

What Are the Different Types of Lathes?

Even though all lathe machines serve the same purpose, there are different types of lathes to be aware of. The number of different lathes is outrageous since lathes are normally designed for specific jobs and functions.

- Speed Lathe Machine

- Engine Lathe Machine

- Belt Drive Lathe Machine

- Motor-Driven Lathe Machine

- Geared-Head Lathe Machine

- Bench Lathe Machine

- Toolroom Lathe Machine

- Capstan and Turret Lathe Machine

- Special purpose lathe machines

- Gap bed lathe machine

- Wheel lathe machine

- Missile lathe machine

- T-lathe machine

- Duplicating lathe machine

- Automatic Lathe Machine

- CNC Lathe Machine

These are just a few examples of the different lathe machines on the market. As you probably can tell from their name, most lathes are determined by their purpose or position. They can also be determined by the main parts within the device.

Of these different varieties, the engine lathe machine is the most common. These models can have multiple spindle speeds and they can cut cross and longitudinal directions. These machines are typically used in workshops in a variety of industries.

Where Is It Used?

Lathes are sometimes called the “mother of machining tools,” and with good reason. These tools can be used for many purposes, ranging from shaping to sanding to drilling to deformation. As such, lathes can be used by a variety of workers in many industries.

The two most common industries that use lathes are woodworking and metalwork. For these industries, lathes are often the basis of the work. If you need precision cutting or precision shaping, a lathe may be the tool you need.

Advantages of a Lathe

Lathes are highly beneficial in commercial settings. They provide precise cuts to ensure you get the shape or patterns that you want. Plus, the fact that there are so many accessories and lathe types means that you can get unmatched precision when using this tool.

At the same time, the tool increases efficiency because it requires so few operators. In the business world, the tool allows the company to save money and time as a result.

Disadvantages of a Lathe

Although lathe machines are beneficial for a number of reasons, they aren’t right for everyone. These tools are not ideal for basic cutting or boring. Not to mention, these machines need constant maintenance to ensure they don’t break prematurely.

You also have to consider the fact that a lathe machine can be incredibly dangerous. If you do not know how to use the lathe, you could seriously injure yourself while using it.

What this means is that a lathe machine is great for commercial purposes, but it is not ideal for individual woodworkers or metalworkers. If you are looking for a tool for hobby purposes, a lathe will likely not be the best choice for you.

Frequently Asked Questions

How does a lathe work?

Lathes remove excess material by exposing the item to a cutting tool within the lathe machine. Inside the machine, the workpiece rotates while being pressed into the cutting tool. This movement allows the product to be quickly and efficiently shaped.

What does a lathe do to wood?

A lathe ultimately removes excess wood whenever the workpiece is made from wood. The wood can be removed in large chunks or small shavings. If you were to put another material inside a lathe machine, the same would be true.

Who should use a lathe?

Lathe machines are an option for commercial woodworkers and metalworkers. It will increase efficiency while perfecting the finish of the product. Hobbyists should not use a lathe because it is not efficient for simple boring purposes, and it can be dangerous.

How to Use a Lathe Safely

As we have already mentioned, using a lathe can be incredibly dangerous. It’s important that you use the machine properly to keep yourself safe. Here are some tips for using a lathe safely:

Wear Protective Gear

Always wear protective gear when working with a lathe. This includes glasses with side protectors or a face shield. You want to tie up your hair, roll up your sleeves, and remove any accessories that could get caught on the lathe. Do not even wear gloves when using this appliance because the gloves can get caught in a spindle.

Check Guards and Shields

Before you begin using the lathe, make sure everything is in the right spot. Always double-check the item. If the machine looks off for any reason, be sure that everyone in your team knows that the machine is broken so accidents do not happen.

Make Adjustments When the Tool Is Powered Off

Do not make any adjustments to the machine if it is running. If you need to move any of the bits inside the lathe, turn the machine off entirely. If you need to perform maintenance, remove the power source before making adjustments or performing maintenance.

Conclusion

Conclusion

To recap, a lathe is a machining tool that is designed to shave or cut away excess material from a wood or metal piece. Because of its purpose, lathes are used in the woodworking and metalworking industries, and there are a variety of lathes available, designed for specific purposes.

If you are a professional, a lathe is a great tool to use. It will offer perfect results while increasing the efficiency of your output. That being said, this tool is often too much and too dangerous for hobbyists. Always make sure to use the lathe safely if you decide the machine is right for you.

Featured Image Credit: Rudimaes, Pixabay

Contents